1 月 . 16, 2025 05:01

Back to list

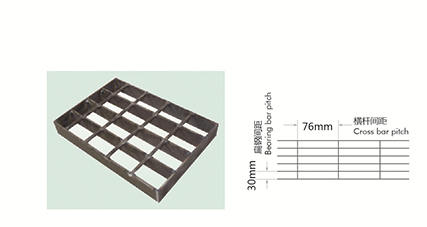

Floor Grating Stainless Steel China Manufacturers Car Grating

Carbon steel grating is an indispensable component across numerous industries due to its robustness, versatility, and cost-effectiveness. As a material expert, I have spent years working hands-on with carbon steel grating, observing its application in various scenarios and industries, which has armed me with invaluable insights into its unique capabilities and advantages.

From a specialist's viewpoint, understanding the technical properties of carbon steel grating is crucial for optimizing its use. The grating typically comprises a series of parallel, equidistant ribs made from carbon steel, which come in a variety of bar sizes and spacing configurations. This flexibility in design allows for tailored solutions to specific load-bearing requirements or aesthetic preferences, whether for industrial flooring, stair treads, or drainage covers. For industries focused on sustainability and environmental impact, it's worth noting that carbon steel grating is recyclable. As industries increasingly embrace environmentally conscious practices, the recyclability of carbon steel aligns with broader sustainability goals, contributing to reduced waste and lower carbon footprints. Indeed, the reputation of carbon steel grating as a trustworthy and authoritative material solution extends beyond its functional benefits. It is endorsed by industry standards and regulations, affirming its reliability and conformance to safety norms. My own extensive experience reinforces this position clients consistently express satisfaction with the material's performance, often citing its resilience and long-term value. Ultimately, carbon steel grating stands out as a robust, reliable, and economical solution for a myriad of applications. It embodies the qualities of strength, safety, and efficiency, making it a preferred choice in environments where these attributes cannot be compromised. My professional journey with carbon steel grating affirms its role as a staple in modern industrial applications, trusted by experts and favored in market solutions worldwide.

From a specialist's viewpoint, understanding the technical properties of carbon steel grating is crucial for optimizing its use. The grating typically comprises a series of parallel, equidistant ribs made from carbon steel, which come in a variety of bar sizes and spacing configurations. This flexibility in design allows for tailored solutions to specific load-bearing requirements or aesthetic preferences, whether for industrial flooring, stair treads, or drainage covers. For industries focused on sustainability and environmental impact, it's worth noting that carbon steel grating is recyclable. As industries increasingly embrace environmentally conscious practices, the recyclability of carbon steel aligns with broader sustainability goals, contributing to reduced waste and lower carbon footprints. Indeed, the reputation of carbon steel grating as a trustworthy and authoritative material solution extends beyond its functional benefits. It is endorsed by industry standards and regulations, affirming its reliability and conformance to safety norms. My own extensive experience reinforces this position clients consistently express satisfaction with the material's performance, often citing its resilience and long-term value. Ultimately, carbon steel grating stands out as a robust, reliable, and economical solution for a myriad of applications. It embodies the qualities of strength, safety, and efficiency, making it a preferred choice in environments where these attributes cannot be compromised. My professional journey with carbon steel grating affirms its role as a staple in modern industrial applications, trusted by experts and favored in market solutions worldwide.

Latest news

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP