Custom Perforated Sheets Versatility and Applications

In today's industrial landscape, the demand for customized solutions is growing rapidly, particularly in the field of manufacturing and construction. One such solution that has garnered attention is the custom perforated sheet. These sheets, characterized by their unique patterns of holes and varying dimensions, offer a range of benefits and applications across different industries.

Understanding Perforated Sheets

Perforated sheets are made from various materials such as metal, plastic, and paper. They are produced by punching holes into a flat sheet, creating a pattern that can be tailored to meet specific requirements. The size, shape, and arrangement of the holes can be customized, allowing for a wide range of functional and aesthetic purposes.

The primary functions of perforated sheets include filtration, ventilation, and aesthetic enhancement. Depending on the application, the perforations can be designed to allow air or light to pass through while providing structural integrity and durability.

Applications in Various Industries

1. Architecture and Design Custom perforated sheets are increasingly popular in architectural applications. They can be used in building facades, screens, and decorative elements. The patterns can be designed to create visual interest while allowing for airflow and light diffusion, contributing to energy efficiency in buildings. For instance, a custom perforated screen can reduce solar heat gain and enhance aesthetics.

2. Automotive Industry In the automotive sector, perforated sheets are utilized for sound dampening and heat management. Custom designs can help manage airflow, reduce weight, and improve the overall performance of vehicles. These sheets can be incorporated into various components, including exhaust systems and body panels, enhancing both functionality and style.

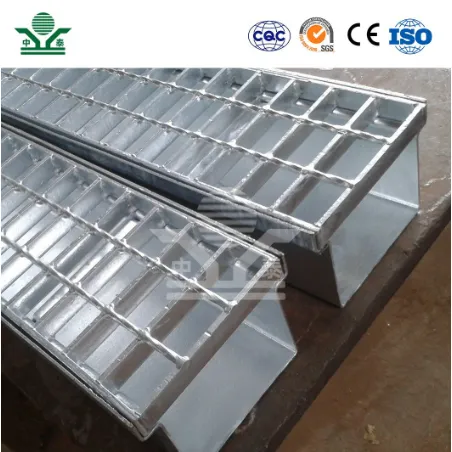

custom perforated sheet

3. Food and Beverage In the food processing industry, custom perforated sheets are essential for various applications, such as filtering and separation processes. They allow for the efficient drainage of liquids while retaining solid particles. Customization ensures that the perforations meet regulatory standards and specific operational requirements.

4. Manufacturing and Industrial The manufacturing sector employs custom perforated sheets for safety and efficiency. They can be used in conveyor systems, safety guards, and equipment enclosures to provide protection while allowing for visibility and adequate ventilation. Custom sheets can be engineered to withstand different loads and environmental conditions, making them ideal for industrial applications.

5. Environmental Applications With growing environmental concerns, custom perforated sheets are being used in applications such as noise reduction barriers and stormwater management systems. These sheets can be designed to facilitate water drainage while filtering pollutants, contributing to sustainable practices in urban planning and infrastructure development.

Advantages of Customization

The customization of perforated sheets provides several advantages. First, it allows businesses to create solutions tailored to their specific needs, which can enhance functionality and performance. Second, custom designs can improve aesthetics, helping businesses create visually appealing products or structures that stand out in a competitive market. Third, with advancements in manufacturing technologies, custom perforated sheets can be produced efficiently, minimizing waste and reducing lead times.

Conclusion

Custom perforated sheets are a versatile solution that plays a crucial role across various industries. Their ability to combine functionality with aesthetic appeal makes them an attractive choice for architects, manufacturers, and engineers alike. As industries continue to evolve and the demand for customized solutions grows, the significance of custom perforated sheets will undoubtedly expand, driving innovation and enhancing the quality of products and structures around us. Embracing this technology can lead to improved safety, efficiency, and sustainability, ensuring that businesses remain competitive in an ever-changing market.

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.