2 月 . 13, 2025 05:59

Back to list

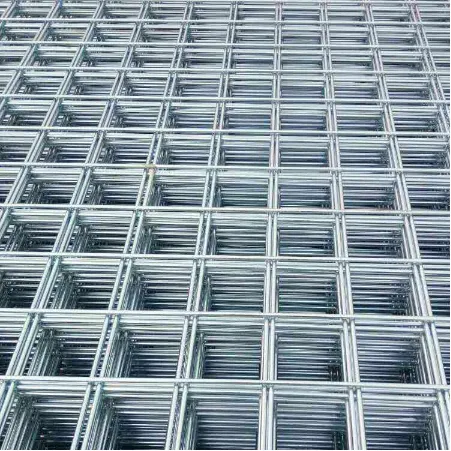

Windproof Dust Suppression Perforated Metal Mesh Anti Wind Net

Dust control fences serve as an essential tool in mitigating environmental and health hazards associated with dust emissions on construction sites, mining areas, and agricultural lands. These fences not only provide a barrier against particulate emissions but also enhance safety and regulatory compliance. Understanding the nuances of their application, installation, and maintenance can greatly benefit contractors and site managers looking to minimize dust pollution effectively.

Authoritativeness in the domain of dust control is underscored by adherence to environmental regulations and guidelines set forth by agencies such as the Environmental Protection Agency (EPA) in the United States. Meeting these standards not only ensures compliance but enhances the reliability and effectiveness of dust control measures on any site. Studies have consistently underscored the importance of maintaining fence integrity, checking regularly for wear and tear, and prompt repairs to extend the lifespan of the dust control solution. The trustworthiness of a dust control solution greatly increases when industry-grade materials and expert installation services are utilized. Suppliers and contractors offering warranties on the durability of their fences can further enhance the confidence in their dust management solutions. Project managers consistently express the need for transparency when choosing dust control providers, emphasizing the inclusion of case studies or references from past clients to validate performance claims. Independent reviews and certifications from environmental bodies also bolster the credibility of products on the market. In conclusion, the deployment of dust control fences is a practiced and reliable method for managing dust emissions in various industries. Accumulated experience demonstrates their effectiveness in improving site air quality and minimizing health risks, while a deep understanding of material choice and installation techniques ensures optimal operation. Emphasizing the authority of compliance with environmental standards and fostering trust through proven performance and transparency are paramount for entities looking to implement dust control measures efficiently and effectively.

Authoritativeness in the domain of dust control is underscored by adherence to environmental regulations and guidelines set forth by agencies such as the Environmental Protection Agency (EPA) in the United States. Meeting these standards not only ensures compliance but enhances the reliability and effectiveness of dust control measures on any site. Studies have consistently underscored the importance of maintaining fence integrity, checking regularly for wear and tear, and prompt repairs to extend the lifespan of the dust control solution. The trustworthiness of a dust control solution greatly increases when industry-grade materials and expert installation services are utilized. Suppliers and contractors offering warranties on the durability of their fences can further enhance the confidence in their dust management solutions. Project managers consistently express the need for transparency when choosing dust control providers, emphasizing the inclusion of case studies or references from past clients to validate performance claims. Independent reviews and certifications from environmental bodies also bolster the credibility of products on the market. In conclusion, the deployment of dust control fences is a practiced and reliable method for managing dust emissions in various industries. Accumulated experience demonstrates their effectiveness in improving site air quality and minimizing health risks, while a deep understanding of material choice and installation techniques ensures optimal operation. Emphasizing the authority of compliance with environmental standards and fostering trust through proven performance and transparency are paramount for entities looking to implement dust control measures efficiently and effectively.

Latest news

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP