Understanding Expanded Mesh Pricing Factors and Considerations

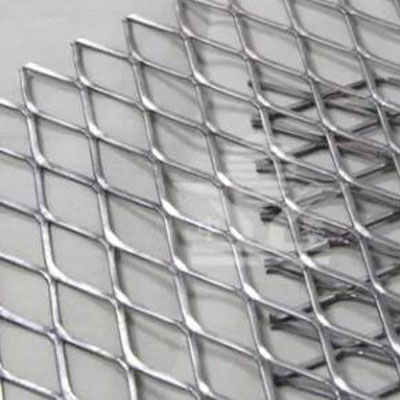

Expanded mesh, often referred to as expanded metal, is a versatile material used in various industries for applications ranging from architectural design to industrial filters. It is created by slitting and stretching a metal sheet, resulting in a mesh pattern that offers strength while reducing weight. As its popularity has surged, so too has interest in understanding the pricing dynamics of expanded mesh. This article explores the factors that influence expanded mesh pricing and offers insights into how buyers can navigate the market effectively.

Factors Influencing Expanded Mesh Pricing

1. Raw Material Costs The price of expanded mesh is heavily influenced by the cost of the base metal used in its production. Common materials include aluminum, stainless steel, carbon steel, and brass. Fluctuations in global metal markets, driven by supply and demand dynamics, tariffs, and geopolitical factors, can lead to price variations. For instance, a surge in demand for aluminum, often tied to the automotive and construction industries, can inflate prices.

2. Manufacturing Process The method by which expanded mesh is produced also plays a significant role in pricing. The machinery used, the complexity of the design, and energy costs impact the overall production expense. Advanced manufacturing techniques or customization requests can increase costs. Moreover, high-quality finishes or coatings used to enhance the material's properties can add to the price.

3. Mesh Specifications The specifications of the expanded mesh, such as thickness, size of the openings, and overall dimensions, also influence pricing. Thicker meshes or those with intricate designs generally require more material and labor, leading to higher costs. Buyers should clearly define their requirements to receive accurate quotes.

4. Market Demand Pricing can also be affected by market demand. During peak construction or manufacturing seasons, demand for expanded mesh can rise sharply, resulting in increased prices. Conversely, during periods of low activity, prices may stabilize or even decrease. Buyers should be aware of seasonal trends in their respective industries when planning purchases.

5. Trade Policies and Tariffs International trade policies can affect the cost of expanded mesh, especially if it is imported. Tariffs imposed on certain metals or materials can lead to increased expenses for manufacturers, which may be passed on to the consumer. Tracking changes in trade agreements and tariffs can help buyers anticipate price changes.

6. Supplier Relationships The relationship between buyers and suppliers can also influence pricing. Established suppliers may offer better rates due to bulk purchasing agreements or long-term contracts. Building strong supplier relationships can lead to better price negotiations and access to premium quality materials.

expanded mesh price

Finding Competitive Pricing

To find competitive pricing for expanded mesh, buyers should take several steps

- Market Research Conduct thorough research to understand standard pricing in the industry. This can involve comparing quotes from multiple suppliers, checking online marketplaces, and consulting industry reports.

- Bulk Buying Purchasing in bulk can often result in significant discounts. Suppliers may be more willing to negotiate prices for larger orders, making it beneficial for companies with regular needs.

- Request Custom Quotes Given the variability in specifications, always request custom quotes tailored to specific requirements. This ensures that you receive a fair price based on your unique needs.

- Negotiate Don’t hesitate to negotiate with suppliers. Many are open to discussions, especially if they see potential for ongoing business.

- Quality vs. Cost While price is important, it is crucial to consider the quality of the expanded mesh. Opting for lower-cost options may result in inferior products that could impact performance and longevity.

Conclusion

Understanding the pricing of expanded mesh is vital for those looking to procure this versatile material. By considering the various factors influencing prices, such as raw material costs, manufacturing processes, and market dynamics, buyers can make informed decisions that align with their budget and quality requirements. By staying proactive and engaging with suppliers, it is possible to navigate the marketplace effectively and secure fair pricing for expanded mesh products.

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.