Understanding Expanded Metal Mesh Manufacturers A Comprehensive Overview

Expanded metal mesh has become a vital component across various industries due to its unique properties and versatile applications. As the demand for this material grows, the role of expanded metal mesh manufacturers becomes increasingly significant. This article delves into the production process, applications, and selection criteria for choosing a reliable manufacturer.

What is Expanded Metal Mesh?

Expanded metal mesh is created by cutting and stretching a metal sheet to produce a mesh-like structure. The process involves making a series of slits in the sheet, which are then pulled apart to form a diamond-shaped opening. This results in a lightweight product with incredible strength and durability. The mesh is available in various materials, including stainless steel, aluminum, and carbon steel, making it suitable for a wide array of applications ranging from architectural designs to industrial uses.

The Manufacturing Process

The manufacturing process of expanded metal mesh involves several crucial steps

1. Material Selection The choice of material depends on the intended application. For instance, stainless steel is often preferred for outdoor use due to its corrosion resistance, while aluminum is favored for applications requiring lightweight solutions.

2. Cutting and Expansion A metal sheet is fed into a specialized machine that accurately cuts slits and expands the sheet simultaneously. This process requires precision to ensure uniform spacing and size of the openings.

3. Finishing After expansion, the mesh may undergo additional treatments, such as coating, painting, or galvanizing, to enhance its appearance and protective features. This step is essential for improving longevity, especially in environments exposed to weather elements.

4. Quality Control A reputable manufacturer places a strong emphasis on quality control measures to ensure that the final product meets industry standards. This may involve testing for factors like strength, durability, and resistance to corrosion.

Applications of Expanded Metal Mesh

Expanded metal mesh has found its applications in various sectors

- Construction Used as interior panels, safety barriers, and architectural features. Its aesthetic quality and functional durability make it ideal for both structural and decorative purposes.

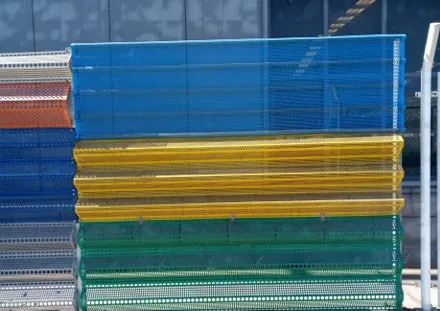

expanded metal mesh manufacturers

- Industrial Employed in filtration systems, walkways, and custom fabrication components

. The mesh's strength helps ensure safety and efficiency in industrial operations.- Automotive Utilized in exhaust systems and noise insulation. The lightweight nature of expanded metal mesh contributes to fuel efficiency while providing necessary structural support.

- Agriculture Often used in fencing, cages for animals, and ventilation screens. Its durability ensures long-lasting solutions in demanding agricultural environments.

Choosing the Right Manufacturer

Selecting the right expanded metal mesh manufacturer is critical to ensuring the quality and reliability of the product. Here are key factors to consider

1. Experience and Reputation Look for manufacturers with a strong industry presence and positive reviews. Experienced companies often have refined processes and a better understanding of customer needs.

2. Product Range A manufacturer offering a diverse range of metals, designs, and finishes can cater to different applications. Customization options demonstrate flexibility and a commitment to meeting specific requirements.

3. Quality Assurance Check if the manufacturer adheres to industry standards and has quality control measures in place. Certifications and compliance with standards can be a good indicator of a reliable supplier.

4. Customer Service Good customer service is essential for addressing any queries and issues that may arise. A manufacturer that prioritizes customer support builds trust and fosters long-term relationships.

5. Competitive Pricing While cost should not be the sole factor, finding a manufacturer that offers competitive pricing without compromising quality is crucial for budget-conscious buyers.

6. Sustainability Practices As industries move towards eco-friendly solutions, consider manufacturers who implement sustainable practices in their production processes. Environmentally conscious choices can contribute to a company’s overall brand reputation.

Conclusion

Expanded metal mesh manufacturers play a pivotal role in supplying this versatile material that impacts several industries. By understanding the manufacturing process, applications, and criteria for choosing a manufacturer, businesses can make informed decisions that enhance their operations. Whether it be for construction, industrial use, or creative design, the role of expanded metal mesh is undeniably significant, and choosing the right supplier can lead to success in any project.

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.