1 月 . 11, 2025 11:29

Back to list

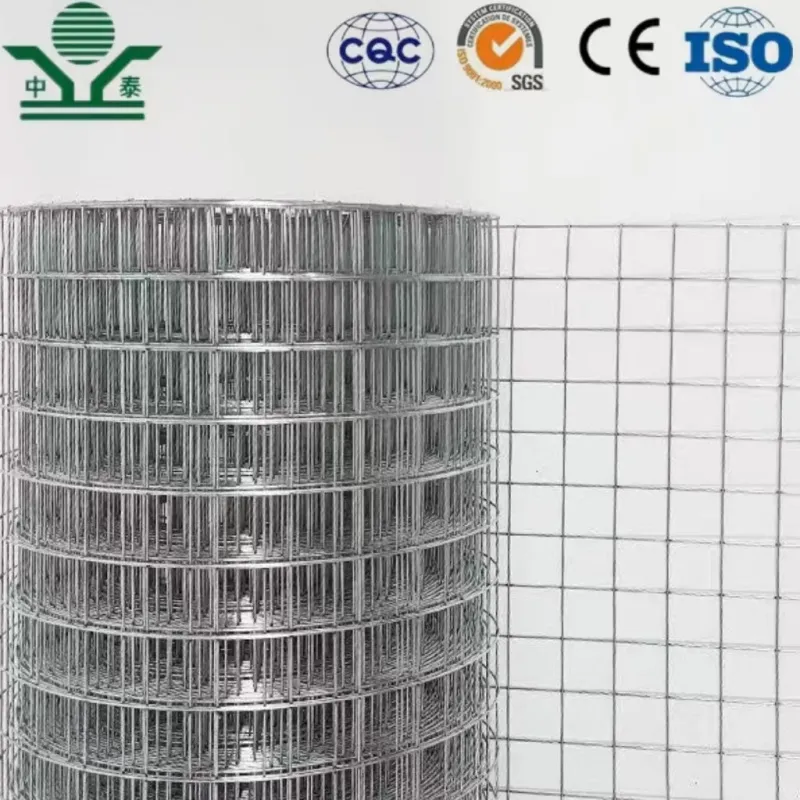

expanded metal mesh sheet sizes

Expanded metal mesh sheets have been integral in various industries, providing unique benefits that are proving indispensable for myriad applications. When considering this versatile material, experience and expertise underscore its value, combining historical application knowledge with cutting-edge advancements to deliver superior performance.

Authoritativeness in deploying expanded metal mesh sheets stems from years of evidence-backed applications and certifications. These sheets conform to stringent international standards, assuring quality and safety across all utilizations. Industries trust expanded metal mesh for its ability to perform under extreme conditions, be it in marine environments where corrosion resistance is crucial or in security settings where intrusion resistance is paramount. Leading manufacturers often collaborate with research institutions, enhancing product reliability and receiving endorsements from regulatory agencies. This authoritative backing translates into peace of mind for engineers, architects, and decision-makers integrating these materials into their projects. Trustworthiness is a critical indicator in selecting expanded metal mesh sheets. The material's inherent strength-to-weight ratio offers balance in applications where both robustness and minimal mass are required. For instance, in aerospace, where every kilogram matters, expanded metal mesh offers reliable solutions without compromising on structural integrity. Over the years, case studies and client testimonials have highlighted not only the material’s performance but also the manufacturers’ commitment to quality assurance and post-purchase support. Engaging with certified suppliers guarantees adherence to best practices and ethical sourcing, further reinforcing consumer confidence. In summary, expanded metal mesh sheets represent a synthesis of experience, expertise, authoritativeness, and trustworthiness. This multidimensional approach to understanding their benefits and applications ensures they remain a go-to material for industry specialists worldwide. Whether for conventional or innovative projects, harnessing the full potential of expanded metal mesh sheets promises enhancements in durability and sustainability, paving the way for future developments that continue to push the boundaries of design and functionality.

Authoritativeness in deploying expanded metal mesh sheets stems from years of evidence-backed applications and certifications. These sheets conform to stringent international standards, assuring quality and safety across all utilizations. Industries trust expanded metal mesh for its ability to perform under extreme conditions, be it in marine environments where corrosion resistance is crucial or in security settings where intrusion resistance is paramount. Leading manufacturers often collaborate with research institutions, enhancing product reliability and receiving endorsements from regulatory agencies. This authoritative backing translates into peace of mind for engineers, architects, and decision-makers integrating these materials into their projects. Trustworthiness is a critical indicator in selecting expanded metal mesh sheets. The material's inherent strength-to-weight ratio offers balance in applications where both robustness and minimal mass are required. For instance, in aerospace, where every kilogram matters, expanded metal mesh offers reliable solutions without compromising on structural integrity. Over the years, case studies and client testimonials have highlighted not only the material’s performance but also the manufacturers’ commitment to quality assurance and post-purchase support. Engaging with certified suppliers guarantees adherence to best practices and ethical sourcing, further reinforcing consumer confidence. In summary, expanded metal mesh sheets represent a synthesis of experience, expertise, authoritativeness, and trustworthiness. This multidimensional approach to understanding their benefits and applications ensures they remain a go-to material for industry specialists worldwide. Whether for conventional or innovative projects, harnessing the full potential of expanded metal mesh sheets promises enhancements in durability and sustainability, paving the way for future developments that continue to push the boundaries of design and functionality.

Latest news

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP