Understanding Expanded Metal Net Versatility and Applications

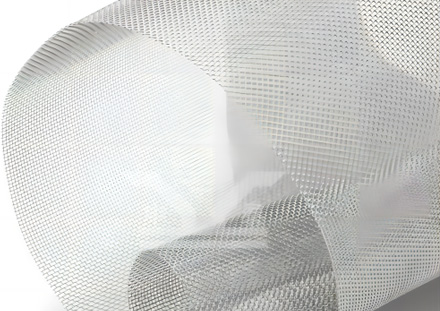

Expanded metal net, often referred to simply as expanded metal, is a unique material that has gained popularity across various industries due to its strength, versatility, and distinct appearance. This innovative product is created by taking a flat sheet of metal and cutting it with a series of slits, which are then stretched to create a diamond-shaped pattern. The result is a lightweight yet robust netting that maintains the integrity of the material while providing numerous practical applications.

Manufacturing Process

The process of creating expanded metal involves a few key steps. Initially, a metal sheet, typically made of steel, aluminum, or other alloys, is subjected to a series of shear cuts. As these cuts are made, the sheet is simultaneously stretched and expanded, forming the characteristic diamond apertures. This manufacturing technique not only enhances the strength of the final product but also reduces waste, making expanded metal a sustainable choice for many projects.

Properties

One of the most appealing characteristics of expanded metal is its strength-to-weight ratio. Despite being lightweight, it is remarkably sturdy, making it suitable for various structural applications. The open design allows for airflow and light penetration, which is particularly beneficial in applications where ventilation is critical. Furthermore, its ability to resist corrosion—especially when made from stainless steel or coated metals—enhances its durability, ensuring that it can withstand harsh environmental conditions.

Applications

expanded metal net

Expanded metal net finds applications in diverse fields. In construction, it serves as a reliable reinforcement for concrete, providing additional structural integrity to buildings and bridges. Its sturdy yet lightweight nature makes it an ideal choice for walkways, stairs, and safety barriers. In the realm of architecture, expanded metal is increasingly used for facades and decorative elements, offering a modern, aesthetically pleasing finish that allows for light and air circulation while maintaining privacy.

In industrial settings, expanded metal is essential for creating safety guards, screens, and shelving. Its open design prevents debris buildup, promoting cleanliness and safety in manufacturing environments. Additionally, it is commonly utilized in the automotive industry for grilles and protection screens, as well as in various applications for furniture design, where its unique appearance can serve a functional and decorative purpose.

Environmental Impact

As industries move toward more sustainable practices, the use of expanded metal net aligns well with these goals. The manufacturing process generates minimal waste compared to traditional metal fabrication methods, and the longevity of the material contributes to reduced replacement needs. Moreover, the ability for expanded metal to be recycled at the end of its life cycle means it can be reintegrated into the material stream, further diminishing its environmental impact.

Conclusion

In summary, expanded metal net is a versatile and effective material that serves a wide range of applications across various industries. Its unique manufacturing process results in a strong and lightweight product that offers numerous benefits, including superior strength, ventilation, and aesthetic appeal. As sustainability becomes a key focus in industrial practices, the role of expanded metal net will likely continue to grow, demonstrating that practicality and environmental responsibility can go hand in hand. As more industries recognize the benefits of this innovative material, expanded metal is poised to remain a staple in construction, design, and manufacturing for years to come.

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.