Exploring Expanded Mild Steel Mesh Versatility and Applications

Expanded mild steel mesh is a highly versatile and widely used material in various industries. Its unique properties and structural integrity make it an essential choice for applications ranging from construction to art installations. This article delves into the characteristics, manufacturing processes, and diverse applications of expanded mild steel mesh.

Characteristics of Expanded Mild Steel Mesh

Expanded mild steel mesh is created from flat mild steel sheets that are cut and stretched to form a mesh pattern. This process results in a lightweight yet strong material with numerous openings that offer both flexibility and durability. The mesh is characterized by its ability to maintain structural integrity while allowing for a significant flow of air, light, and sound.

One of the significant advantages of expanded mild steel mesh is its excellent strength-to-weight ratio. This makes it a preferred choice for projects where weight reduction is essential without compromising on strength. Additionally, the open mesh structure promotes ventilation, which is invaluable in numerous applications, particularly in the construction and automotive sectors.

The surface of expanded mild steel mesh can be treated in various ways, including galvanization, powder coating, or painting. These treatments enhance the material's resistance to corrosion and ensure a longer lifespan, making it suitable for outdoor and harsh environments.

Manufacturing Process

The manufacturing process of expanded mild steel mesh involves several steps. Initially, flat sheets of mild steel are subjected to cutting and expanding. Specialized machines cut the sheets into a predetermined pattern before they are stretched or expanded. This results in a mesh with a unique diamond or hexagonal shape, depending on the design requirements.

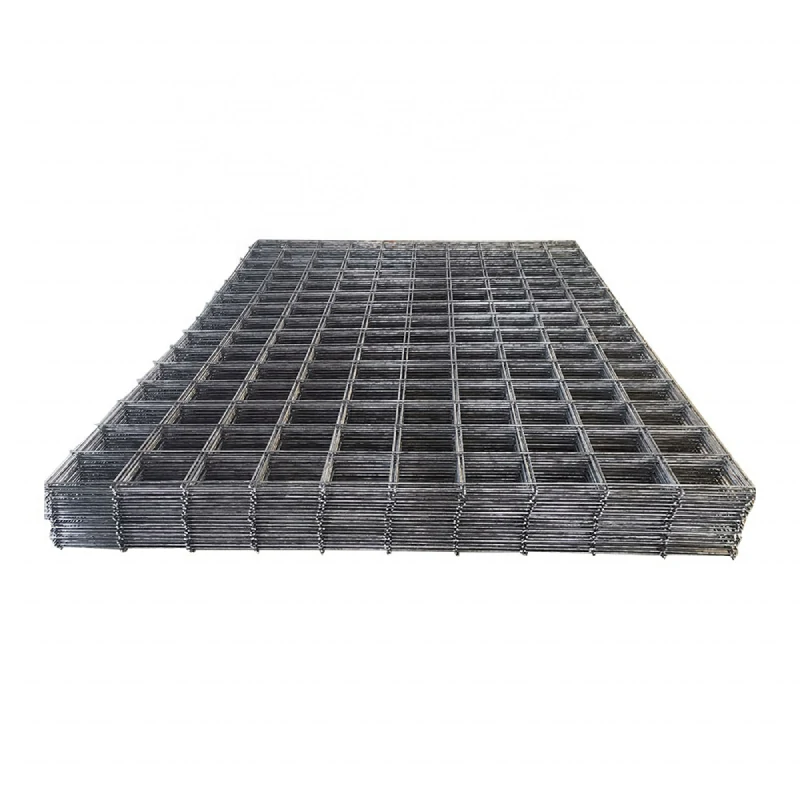

expanded mild steel mesh

The thickness of the steel and the size of the openings can be customized during production, allowing for tailored solutions that meet specific project needs. The versatility in design means that expanded mild steel mesh can be used in a wide range of applications, adapting to the demands of both industrial and aesthetic purposes.

Applications of Expanded Mild Steel Mesh

Expanded mild steel mesh is widely used across various sectors due to its versatility. One of the primary uses is in the construction industry, where it serves as material for walls, ceilings, and flooring. The mesh allows for proper ventilation and is often used in soundproofing and acoustic applications, creating environments conducive to concentration and focus.

In addition to construction, expanded mild steel mesh finds applications in the automotive industry, where it is used for grilles and safety barriers. Its lightweight nature contributes to fuel efficiency, while its robustness ensures vehicle safety. Moreover, it is also employed in the manufacturing of storage cages, shelving, and platforms, providing support while maintaining accessibility.

Another notable application is in the realm of art and decor. Artists and designers utilize expanded mild steel mesh to create striking visual pieces, sculptures, and installations. Its aesthetic appeal combined with its structural capabilities allows for innovative designs that captivate audiences.

Conclusion

Expanded mild steel mesh is a remarkable material that embodies strength, versatility, and aesthetic potential. Its robust properties make it suitable for a myriad of applications across different industries, from construction to art. As technology advances, the capabilities and uses of expanded mild steel mesh continue to evolve, further establishing its role as an essential material in modern design and manufacturing. Whether for structural, functional, or artistic purposes, expanded mild steel mesh exemplifies the intersection of strength and creativity, making it a ubiquitous component in today’s projects.

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.