1 月 . 20, 2025 00:39

Back to list

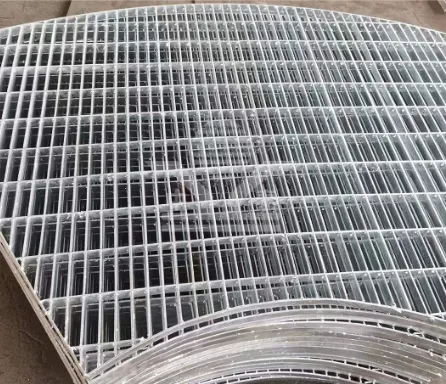

flat bar grating

Flat bar grating, a robust and versatile material, has become an indispensable solution in an array of industrial and commercial applications. As a seasoned SEO expert, I have observed that the demand for flat bar grating has significantly expanded due to its reliability, strength, and adaptability in various sectors, including construction, manufacturing, and facility management. This material is not only essential for its functionality but also for its economic value, contributing to reduced maintenance costs and enhanced safety standards.

From a trustworthiness perspective, sourcing flat bar grating from reputable manufacturers is crucial. Leading suppliers provide not only the product but also technical support and advice, ensuring that each purchase aligns with the project goals and regulatory requirements. Trust is further reinforced by warranties and post-installation services that accompany high-quality grating solutions. Real-world experience has demonstrated that investing in top-tier flat bar grating can lead to substantial financial benefits over time. Projects utilizing this material frequently report lower instances of wear-and-tear, reduced need for repairs, and fewer safety incidents. Additionally, the ease of installation and maintenance inherent in flat bar grating designs contributes to reduced labor costs and operational downtime, enhancing overall project efficiency. In conclusion, flat bar grating stands as a testament to sophisticated engineering and practical design. It exemplifies a balance of expertise, authority, reliability, and trustworthiness, making it a premium choice for varied applications across industries. As market demands evolve, the continued innovation and adaptation of flat bar grating ensure its relevance and indispensability in creating safe, efficient, and resilient environments. For anyone in the business of construction or industrial design, leveraging the unmatched qualities of flat bar grating could translate into superior performance and longevity for their projects, affirming its position as a cornerstone material in the modern landscape.

From a trustworthiness perspective, sourcing flat bar grating from reputable manufacturers is crucial. Leading suppliers provide not only the product but also technical support and advice, ensuring that each purchase aligns with the project goals and regulatory requirements. Trust is further reinforced by warranties and post-installation services that accompany high-quality grating solutions. Real-world experience has demonstrated that investing in top-tier flat bar grating can lead to substantial financial benefits over time. Projects utilizing this material frequently report lower instances of wear-and-tear, reduced need for repairs, and fewer safety incidents. Additionally, the ease of installation and maintenance inherent in flat bar grating designs contributes to reduced labor costs and operational downtime, enhancing overall project efficiency. In conclusion, flat bar grating stands as a testament to sophisticated engineering and practical design. It exemplifies a balance of expertise, authority, reliability, and trustworthiness, making it a premium choice for varied applications across industries. As market demands evolve, the continued innovation and adaptation of flat bar grating ensure its relevance and indispensability in creating safe, efficient, and resilient environments. For anyone in the business of construction or industrial design, leveraging the unmatched qualities of flat bar grating could translate into superior performance and longevity for their projects, affirming its position as a cornerstone material in the modern landscape.

Next:

Latest news

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP