Galvanized Steel Grating Platforms An Essential Element for Modern Infrastructure

In the realm of industrial infrastructure, safety, durability, and efficiency are paramount. One of the cornerstones of modern construction that addresses these needs is the galvanized steel grating platform. This versatile material combines strength with a range of functional benefits, making it a favored choice in various applications.

Understanding Galvanized Steel Grating

Galvanized steel grating is made from steel bars that are welded together in a grid pattern and coated with a layer of zinc to protect against corrosion. The galvanization process involves immersing the steel in molten zinc, which adheres to the surface and creates a protective barrier. This not only enhances the lifespan of the grating but also reduces maintenance costs significantly, as it prevents rust and degradation over time.

The design of steel grating platforms offers excellent load-bearing capabilities while allowing for efficient drainage. These platforms are characterized by their open design, which provides superior slip resistance—a critical safety feature in industrial environments. The gaps in the grating allow liquid and debris to pass through, reducing the risk of buildup and creating safer working conditions.

Applications of Galvanized Steel Grating Platforms

Galvanized steel grating platforms can be found in a variety of settings, including industrial plants, commercial buildings, and public infrastructure. They are commonly used in the following applications

1. Walkways and Stairways With their slip-resistant surface and sturdy construction, galvanized steel gratings are ideal for external walkways, staircases, and catwalks. They provide secure footing, even in wet or oily conditions, making them a preferred choice for factories and warehouses.

2. Platforms and Sub-floors In many industrial applications, elevated platforms are necessary for maintenance and operational efficiency. Steel grating can be employed as the flooring for these platforms, allowing for both structural integrity and enhanced ventilation.

3. Trench Covers and Drainage Systems Many facilities incorporate trench drains to manage wastewater and prevent flooding. Galvanized steel grating serves as effective trench covers, ensuring safety while allowing for unobstructed drainage.

galvanized steel grating platform

4. Safety Railings and Fencing The inherent strength of galvanized steel combined with its resistance to rust makes it an excellent choice for safety railings and fencing around various platforms, ensuring that individuals are protected from falls and accidents.

Advantages of Using Galvanized Steel Grating Platforms

1. Corrosion Resistance The zinc coating provides a robust shield against moisture and chemicals, significantly extending the life of the grating.

2. Cost-Effective Although the initial investment might be higher than other materials, the long-term savings on maintenance and replacements make galvanized steel gratings a cost-effective solution.

3. Safety With their anti-slip properties and load-bearing capacity, these platforms promote a safer working environment, minimizing the risks of accidents.

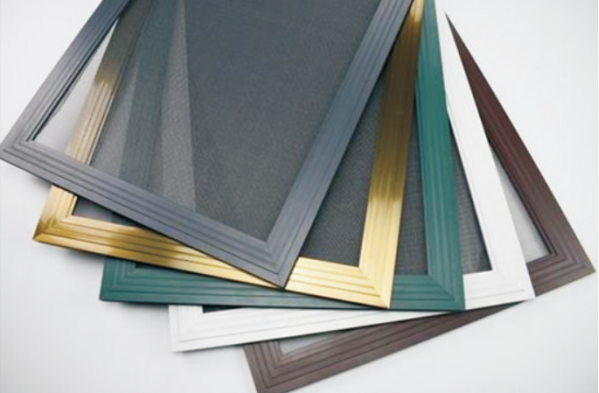

4. Customizability Galvanized steel grating can be manufactured in various sizes, shapes, and load ratings, allowing for tailored solutions that meet specific project requirements.

5. Easy Installation and Maintenance The lightweight nature of galvanized steel makes installation straightforward, and the low maintenance requirements mean that once installed, they provide years of service with minimal intervention.

Conclusion

Galvanized steel grating platforms are not just an industrial product; they represent a crucial advancement in the pursuit of safety and efficiency in modern construction. Their diverse applications, strength, and corrosion resistance make them indispensable in multiple sectors, including manufacturing, construction, and waste management. As we continue to advance in the fields of infrastructure and safety, galvanized steel grating platforms will undoubtedly play a significant role in shaping the environments where we work and live. For anyone involved in construction or industrial operations, investing in this material is a step toward ensuring durability, safety, and efficiency in their projects.

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.