1 月 . 31, 2025 03:12

Back to list

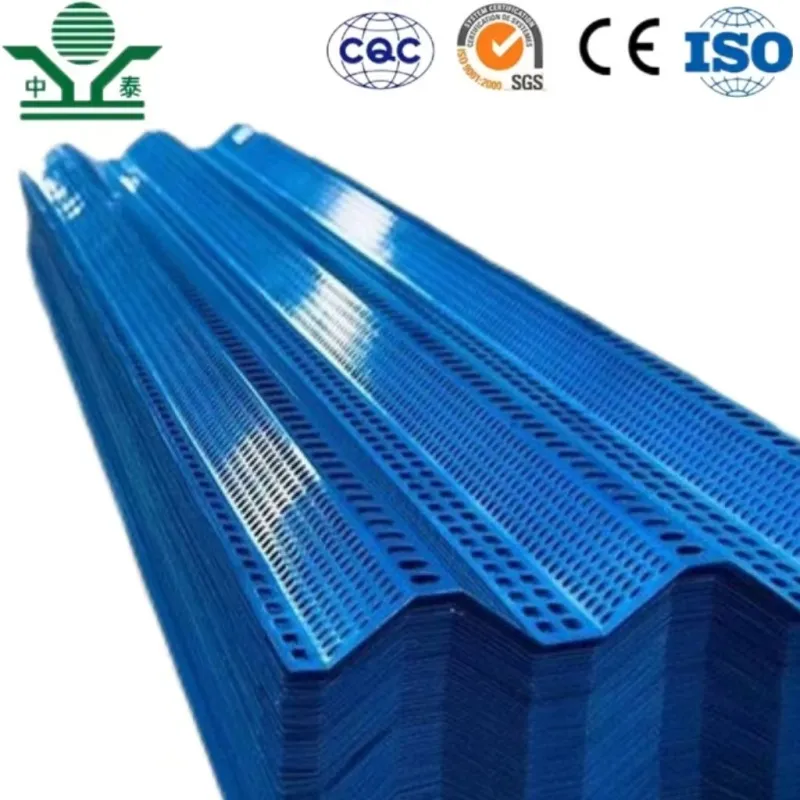

mesh perforated sheet

Mesh perforated sheets have revolutionized various industries by providing a versatile and practical material that combines durability with aesthetic appeal. These sheets - made from materials such as stainless steel, aluminum, or copper - have been expertly crafted to meet a wide array of applications, making them an indispensable resource in modern construction, architecture, and design.

Trustworthiness is a critical factor when selecting mesh perforated sheets for any project. Reputable suppliers and manufacturers adhere to stringent quality control processes, ensuring the sheets possess uniform thickness, hole size, and pattern consistency. They provide certifications and rigorous testing results to back their claims, giving customers peace of mind about the product’s performance and safety. Additionally, the maintenance requirements for these sheets are minimal, which further enhances their reliability and cost-effectiveness over time. In the realm of design, mesh perforated sheets offer unmatched versatility. Architects and designers leverage the unique textures and patterns of these sheets to create striking visual contrasts in both interior and exterior applications. Whether aiming for a modern, industrial look or a more intricate, artistic design, the adaptability of these sheets serves as a canvas for creative exploration. In conclusion, mesh perforated sheets are a testament to the blend of engineering ingenuity and aesthetic flexibility. Their application across diverse sectors showcases their essential role in modern innovation and design. By understanding the material’s capabilities and limitations, professionals can maximize its potential, ensuring successful implementation in their projects. This reliable, innovative, and adaptable material continues to be sought after by industries worldwide, proving its worth as a cornerstone in the realm of contemporary design and construction.

Trustworthiness is a critical factor when selecting mesh perforated sheets for any project. Reputable suppliers and manufacturers adhere to stringent quality control processes, ensuring the sheets possess uniform thickness, hole size, and pattern consistency. They provide certifications and rigorous testing results to back their claims, giving customers peace of mind about the product’s performance and safety. Additionally, the maintenance requirements for these sheets are minimal, which further enhances their reliability and cost-effectiveness over time. In the realm of design, mesh perforated sheets offer unmatched versatility. Architects and designers leverage the unique textures and patterns of these sheets to create striking visual contrasts in both interior and exterior applications. Whether aiming for a modern, industrial look or a more intricate, artistic design, the adaptability of these sheets serves as a canvas for creative exploration. In conclusion, mesh perforated sheets are a testament to the blend of engineering ingenuity and aesthetic flexibility. Their application across diverse sectors showcases their essential role in modern innovation and design. By understanding the material’s capabilities and limitations, professionals can maximize its potential, ensuring successful implementation in their projects. This reliable, innovative, and adaptable material continues to be sought after by industries worldwide, proving its worth as a cornerstone in the realm of contemporary design and construction.

Next:

Latest news

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP