The Importance of Metal Safety Grating in Modern Infrastructure

Metal safety grating is an essential component in various industrial and commercial applications, serving as a reliable solution for safety, accessibility, and drainage. This material plays a crucial role in environments that require a durable and slip-resistant underfoot surface, making it a popular choice across sectors such as construction, manufacturing, and wastewater management. In this article, we will explore the benefits, applications, and maintenance of metal safety grating.

Understanding Metal Safety Grating

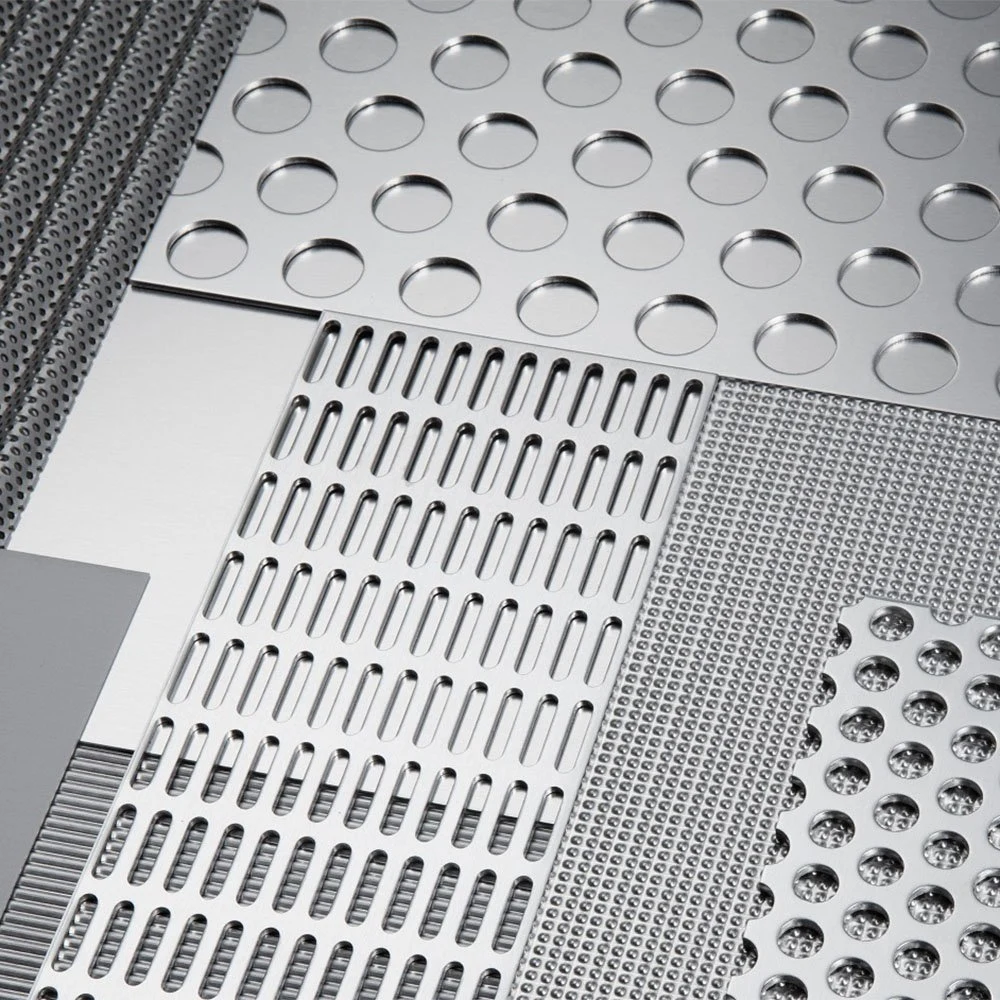

Metal safety grating is typically made from materials like steel, aluminum, or stainless steel, which provide strength, durability, and resistance to corrosion. It is designed with an open grid pattern, allowing for optimal drainage and visibility. The grating can be customized in various sizes, shapes, and load-bearing capacities, making it suitable for a wide range of applications, from walkways and platforms to stair treads and drainage covers.

Benefits of Metal Safety Grating

One of the primary advantages of metal safety grating is its slip-resistant surface. Many designs feature an anti-slip coating or serrated surfaces that enhance traction, significantly reducing the risk of accidents in wet or oily environments. This safety feature is particularly vital in industries such as food processing, pharmaceuticals, and chemical handling, where spills and slip hazards are common.

Moreover, metal safety grating is known for its exceptional load-bearing capabilities. It can support heavy machinery and foot traffic, making it an ideal choice for industrial settings. The lightweight yet robust design allows for easy installation and maintenance, which can help reduce labor costs and downtime.

Corrosion resistance is another critical benefit of metal safety grating. When manufactured from materials like stainless steel or galvanized steel, the grating can withstand harsh environmental conditions, including exposure to chemicals, moisture, and extreme temperatures. This durability translates into long service life, reducing the need for frequent replacements.

Applications of Metal Safety Grating

metal safety grating

Metal safety grating finds application across various sectors. In the construction industry, it is often used for walkways, catwalks, and platforms where safety and visibility are paramount. Grating systems facilitate safe movement for workers and equipment while ensuring efficient management of liquid runoff.

In manufacturing settings, especially in facilities dealing with hazardous materials, metal safety grating provides essential safety features. It allows for easy cleanup and maintenance, reducing the risk of workplace accidents. Additionally, its customization options enable the design of grates that meet specific load and safety requirements.

Wastewater treatment plants utilize metal safety grating in filtration systems and access platforms. The open grid design aids in efficient drainage while providing safe access for maintenance personnel. In this context, the durability and corrosion resistance of metal grating can significantly extend the lifespan of the installation.

Maintenance of Metal Safety Grating

To ensure the longevity and effectiveness of metal safety grating, proper maintenance is essential. Regular inspections should be conducted to identify any signs of wear, corrosion, or damage. Cleaning the grating periodically helps prevent the buildup of debris, which can impede water drainage and contribute to slip hazards.

In environments exposed to corrosive substances, applying protective coatings can enhance the lifespan of the grating. It is also advisable to address any minor repairs promptly to prevent more extensive damage that could compromise safety.

Conclusion

Metal safety grating is a vital element in maintaining safety and efficiency in industrial and commercial applications. With its slip-resistant properties, load-bearing capabilities, and resistance to corrosion, it is an indispensable tool in various sectors. As industries continue to prioritize safety, the relevance of metal safety grating will only grow, ensuring that workplaces remain secure and accessible for all. Whether used in construction, manufacturing, or wastewater management, the right metal safety grating can significantly enhance operational safety and performance. Investing in quality grating not only meets regulatory standards but also fosters a culture of safety that benefits employees and employers alike.

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.