1 月 . 31, 2025 04:44

Back to list

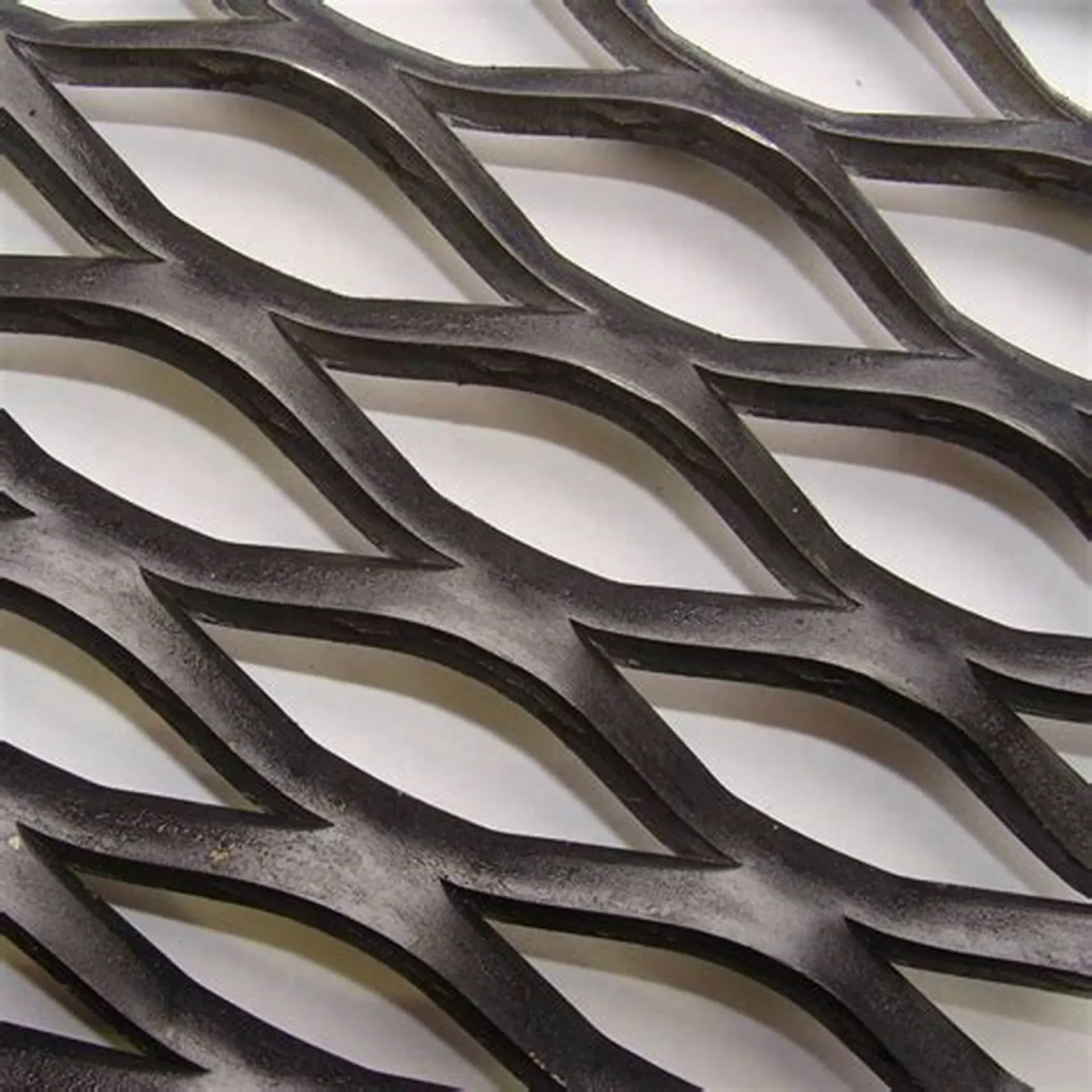

Perforated Metal Sheet #8 Mesh China Manufacturing Perforated Mesh Plastic Sheet

Metal sheets with small holes, often known as perforated metal sheets, have revolutionized the world of engineering and design by their blend of functionality and aesthetics. This unique material has seeped into various industries owing to its array of benefits, backed by professional analysis, considerable usage history, and consistent demand. The product marries practical utility with an innovative appeal, positioning itself as an indispensable commodity across multiple domains.

The trustworthiness of metal sheets with small holes is reinforced by their significant environmental benefits. These sheets contribute to sustainable development goals by enabling energy efficiency and recycling advantages. Their design can facilitate natural light entry and air circulation in buildings, significantly reducing dependence on artificial lighting and climate control systems, thereby cutting down energy consumption. Furthermore, the recyclability of metals used in these sheets aligns with global efforts for circular economy practices, gaining the trust of eco-conscious architects and builders. Product innovation and customization remain at the core of perforated metal sheets’ appeal. The ability to adjust hole sizes, patterns, and metal types means these sheets can be fine-tuned to meet the specific demands of any project—be it enhancing the acoustics of a music venue or ensuring the longevity and aesthetics of a new skyscraper’s facade. This adaptability not only enhances their utility but also solidifies their place as a preferred choice in sophisticated engineering and design solutions. In conclusion, metal sheets with small holes exemplify a fusion of art and science, epitomizing modern advancements in material technology. The synergy between their expert-driven design, methodological production, and authoritative applications fosters a level of trust unrivaled in many other building materials. As industries continue to innovate and evolve, the reliance on these versatile sheets is expected to expand, underlining their significance and potential in crafting the future architectural and industrial landscapes.

The trustworthiness of metal sheets with small holes is reinforced by their significant environmental benefits. These sheets contribute to sustainable development goals by enabling energy efficiency and recycling advantages. Their design can facilitate natural light entry and air circulation in buildings, significantly reducing dependence on artificial lighting and climate control systems, thereby cutting down energy consumption. Furthermore, the recyclability of metals used in these sheets aligns with global efforts for circular economy practices, gaining the trust of eco-conscious architects and builders. Product innovation and customization remain at the core of perforated metal sheets’ appeal. The ability to adjust hole sizes, patterns, and metal types means these sheets can be fine-tuned to meet the specific demands of any project—be it enhancing the acoustics of a music venue or ensuring the longevity and aesthetics of a new skyscraper’s facade. This adaptability not only enhances their utility but also solidifies their place as a preferred choice in sophisticated engineering and design solutions. In conclusion, metal sheets with small holes exemplify a fusion of art and science, epitomizing modern advancements in material technology. The synergy between their expert-driven design, methodological production, and authoritative applications fosters a level of trust unrivaled in many other building materials. As industries continue to innovate and evolve, the reliance on these versatile sheets is expected to expand, underlining their significance and potential in crafting the future architectural and industrial landscapes.

Latest news

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP