1 月 . 10, 2025 08:43

Back to list

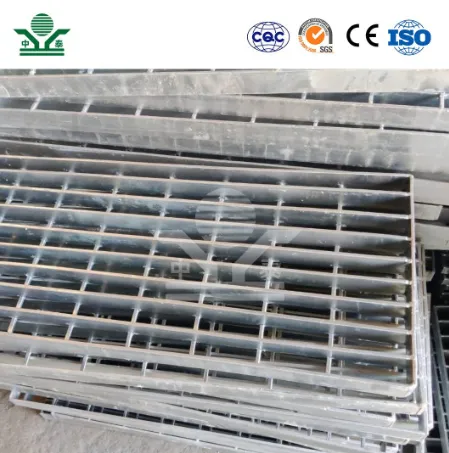

micro expanded metal mesh

Micro expanded metal mesh serves as a revolutionary material in the construction and industrial sectors, renowned for its versatility and robustness. As top architects and engineers move towards sustainable and cost-effective solutions, this material is establishing itself as a valuable asset in myriad applications. From façade cladding in modern skyscrapers to efficient filtration systems in the medical sector, micro expanded metal mesh is ushering in a new era of technological advancement.

Moreover, its use in safety and security sectors underscores the mesh's authoritative standing. Many global enterprises trust micro expanded metal mesh for safeguarding facilities, as it provides a secure yet flexible barrier. Its resistance to cutting and impact makes it an ideal solution for fencing, window guards, and machine enclosures. In sectors such as agriculture and food processing, micro expanded metal mesh’s trustworthiness shines through again. Here, its sanitary and non-toxic properties, combined with exceptional strength, allow for effective separation and filtration processes, ensuring compliance with strict hygiene standards. The material's adaptability to both high and low temperatures further cements its standing as a go-to solution in diverse environments. Furthermore, industry professionals frequently highlight positive experiences with micro expanded metal mesh, citing its ease of installation and minimal maintenance requirements as substantial benefits. Reports acclaim its performance, noting how its integration into existing systems leads to optimized operations and reduced costs over time. In conclusion, micro expanded metal mesh stands as a beacon of innovation, authority, and trustworthiness in advancing technology and design. Its expert craftsmanship and capacity to meet diverse, high-performance demands give it unparalleled credibility in the competitive world market. As industries continue to evolve, the micro expanded metal mesh remains pivotal in supporting sustainable and avant-garde practices, rightly earning its place as a cornerstone material in the 21st century.

Moreover, its use in safety and security sectors underscores the mesh's authoritative standing. Many global enterprises trust micro expanded metal mesh for safeguarding facilities, as it provides a secure yet flexible barrier. Its resistance to cutting and impact makes it an ideal solution for fencing, window guards, and machine enclosures. In sectors such as agriculture and food processing, micro expanded metal mesh’s trustworthiness shines through again. Here, its sanitary and non-toxic properties, combined with exceptional strength, allow for effective separation and filtration processes, ensuring compliance with strict hygiene standards. The material's adaptability to both high and low temperatures further cements its standing as a go-to solution in diverse environments. Furthermore, industry professionals frequently highlight positive experiences with micro expanded metal mesh, citing its ease of installation and minimal maintenance requirements as substantial benefits. Reports acclaim its performance, noting how its integration into existing systems leads to optimized operations and reduced costs over time. In conclusion, micro expanded metal mesh stands as a beacon of innovation, authority, and trustworthiness in advancing technology and design. Its expert craftsmanship and capacity to meet diverse, high-performance demands give it unparalleled credibility in the competitive world market. As industries continue to evolve, the micro expanded metal mesh remains pivotal in supporting sustainable and avant-garde practices, rightly earning its place as a cornerstone material in the 21st century.

Latest news

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP