Understanding Perforated Aluminum Sheets A Focus on 4x8 Dimensions

Perforated aluminum sheets have gained significant popularity across various industries, thanks to their versatility, durability, and aesthetic appeal. A particular size that frequently emerges in the market is the 4x8 perforated aluminum sheet. This dimension, measuring four feet by eight feet, strikes a perfect balance between usability and manageability, making it an ideal choice for numerous applications.

Understanding Perforated Aluminum Sheets A Focus on 4x8 Dimensions

Moreover, the aesthetic versatility of perforated aluminum sheets cannot be overlooked. The patterns created by the perforations can be customized to suit specific design requirements, making them a popular choice for decorative applications. Whether used as a façade in modern architecture or as a privacy screen in landscaping, these sheets offer both functional and artistic value. The ability to allow light and air to pass through while still providing a visual barrier is a unique advantage that many designers capitalize on.

perforated aluminum sheet 4x8

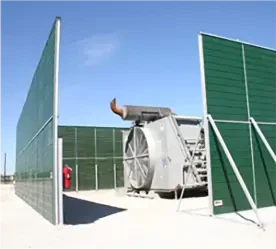

In terms of functionality, perforated aluminum sheets serve multiple purposes. They are commonly used in the fabrication of grilles, filters, and sound barriers due to their ability to facilitate airflow while preventing larger particles from passing through. This makes them ideal for applications in HVAC systems and industrial environments where air circulation is vital. Furthermore, thanks to their corrosion-resistant properties, aluminum sheets contribute to the longevity of these installations, making them a cost-effective solution for both short-term projects and long-term investments.

When considering a 4x8 perforated aluminum sheet, one must also think about the hole patterns and sizes. The choice of perforation affects not only the aesthetics but also the functionality of the sheet. Larger holes may provide better airflow but can compromise strength in certain applications, while smaller holes allow finer filtration but may reduce overall material strength. It's vital for manufacturers and designers to work closely together to determine the optimal configuration that meets both structural and operational requirements.

Additionally, the ease of maintenance associated with perforated aluminum sheets makes them a practical choice for various applications. A simple wipe down with a damp cloth is often sufficient to keep the surface clean, as aluminum naturally resists rust and corrosion. This low maintenance requirement not only saves time but also ensures that the installations remain visually appealing for years to come.

In conclusion, the versatility of 4x8 perforated aluminum sheets makes them an essential material across different sectors. From architecture and design to industrial applications, their lightweight nature, aesthetic options, and functional benefits position them as a top choice for builders, designers, and engineers alike. As industries continue to innovate, the demand for such materials is likely to grow, leading to even more creative uses and applications in the future. Whether one is looking to enhance the aesthetics of a space or improve functionality in an industrial setting, perforated aluminum sheets provide a reliable and attractive solution.

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.