Exploring Perforated Sheet Metal Patterns

Perforated sheet metal has emerged as a popular choice in various industries, thanks to its unique combination of functionality and aesthetic appeal. This versatile material, characterized by a pattern of holes or slots punched into sheets of metal, has applications that range from architectural design to industrial equipment, making it a fascinating subject for exploration. In this article, we will delve into the different patterns of perforated sheet metal, their uses, advantages, and design considerations.

The Basics of Perforated Sheet Metal

At its core, perforated sheet metal is produced by systematically punching holes into a metal sheet, resulting in a product that can vary in thickness, size, and hole pattern. Common materials used for perforated sheets include stainless steel, aluminum, and carbon steel. The choice of material often depends on the intended application, with considerations for durability, corrosion resistance, and weight.

Patterns and Designs

The aesthetic flexibility of perforated sheet metal is one of its standout features. The patterns can be simple or complex, ranging from uniform circular holes to intricate geometric shapes. Some of the most common patterns include

1. Round Holes This pattern is the most popular due to its versatility. Round holes can be arranged in a staggered or straight layout, offering a functional yet elegant solution for ventilation, light diffusion, and privacy screens.

2. Square and Rectangular Holes Square holes provide an industrial aesthetic and are often used in applications where larger airflow is required, such as HVAC systems. They can also function as a decorative element, especially in contemporary settings.

3. Custom Patterns Businesses often request custom designs that reflect their brand or specific functional needs. These unique patterns can include logos or artistic motifs, allowing for a degree of personalization that is particularly appealing in architectural applications.

Applications of Perforated Sheet Metal

Perforated sheet metal is utilized across a vast array of industries for several reasons.

- Architectural Design In modern architecture, perforated metal facades are used for both functional and decorative purposes. They provide shade, reduce solar heat gain, and offer a unique visual element that enhances the building’s design.

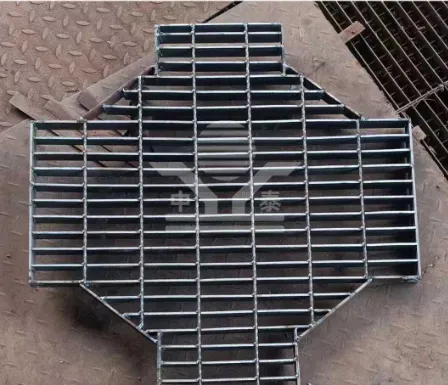

perforated sheet metal patterns

- Acoustic Panels The sound absorption properties of perforated sheets make them ideal for use in places where controlling noise levels is essential, such as auditoriums and theaters

.- Industrial Uses Perforated sheets are widely employed in the manufacturing sector, often serving as filters, screens, or guards. Their robust nature makes them suitable for applications in machines, conveyors, and food processing.

- Furniture and Interior Design Designers are increasingly using perforated metal to create furniture pieces and interior elements, such as room dividers and shelving units, that balance style and functionality.

Advantages of Using Perforated Sheet Metal

The advantages of perforated sheet metal extend beyond aesthetics. Some notable benefits include

1. Lightweight yet Strong Despite its lightweight nature, perforated metal retains strength and durability, making it a reliable choice for various applications.

2. Improved Airflow and Light Transmission The arrangement of holes allows for significant airflow and light diffusion, making it ideal for ventilation systems and daylighting applications.

3. Customization Manufacturers can easily create custom patterns, hole sizes, and layouts tailored to specific project requirements, offering a wide range of design possibilities.

4. Sustainability Many perforated metal sheets are made from recyclable materials, and their durability often extends their life cycle, contributing to more sustainable building practices.

Conclusion

Perforated sheet metal stands out as a dynamic material that successfully combines form and function. Whether through intricate custom designs or simple, practical applications, the patterns created in perforated sheet metal have a significant impact across various industries. As the demand for innovative building materials increases, the relevance of perforated sheets in architectural and industrial design will continue to grow. With its myriad of applications and advantages, it is clear that perforated sheet metal is not just a functional product but also a critical component of modern design and engineering.

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.