Understanding Reverse Dutch Weave Wire Mesh Applications and Benefits

Wire mesh is a staple in various industries, known for its versatility and strength. Among the different types of wire mesh, reverse Dutch weave wire mesh has carved a niche for itself due to its unique structure and numerous applications. This article delves into what reverse Dutch weave wire mesh is, how it differs from other types, and where it is commonly used.

What is Reverse Dutch Weave Wire Mesh?

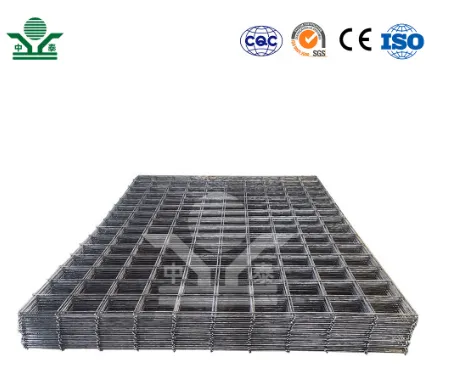

Reverse Dutch weave wire mesh is a type of woven wire screen characterized by its specific interlacing pattern. In this mesh, the wires are woven together in a way that is distinct from the traditional Dutch weave. Instead of having the warp wires (the longitudinal wires) thicker and the weft wires (the horizontal wires) thinner, reverse Dutch weave inverts this structure. The result is a more robust mesh with a finer aperture that is still capable of withstanding high pressures.

The manufacturing process involves weaving thin wires in a series of alternating patterns, creating a dense yet permeable fabric. This unique arrangement not only enhances durability but also provides effective filtration properties, making it suitable for a range of demanding applications.

Key Features of Reverse Dutch Weave Wire Mesh

1. Strength and Durability One of the most significant advantages of reverse Dutch weave wire mesh is its strength. The interlacing technique used adds structural integrity, making it suitable for heavy-duty applications.

2. Fine Filtration The fine openings between the wires make this mesh particularly effective for filtration processes. It can screen out smaller particles while allowing fluids or gases to pass, making it ideal for various industrial applications.

3. Corrosion Resistance Depending on the material used (often stainless steel), reverse Dutch weave wire mesh can resist corrosion, enhancing its lifespan and making it suitable for use in harsh environments.

reverse dutch weave wire mesh

Applications of Reverse Dutch Weave Wire Mesh

Reverse Dutch weave wire mesh is employed in various industries, each utilizing its unique properties for different purposes. Some of the common applications include

1. Oil and Gas Industry Due to its high strength and excellent filtration abilities, reverse Dutch weave wire mesh is used in the oil and gas sector for well screen applications. It helps filter out sand and other particulates, ensuring the efficient and safe extraction of resources.

2. Food and Beverage Processing In the food industry, reverse Dutch weave wire mesh plays a critical role in separation and filtration processes. It is commonly used in the manufacturing of beverages and other food products to ensure purity and compliance with health standards.

3. Pharmaceutical Manufacturing The pharmaceutical industry requires materials that meet stringent cleanliness and filtration criteria. Reverse Dutch weave wire mesh is utilized to filter out contaminants and ensure product integrity.

4. Chemical Processing This mesh is also useful in chemical processing, where it separates chemicals and solids during production, ensuring the final products are of the desired quality and consistency.

5. Environmental Applications In environmental engineering, reverse Dutch weave wire mesh is used in waste management and water treatment processes to filter and separate harmful substances from water or soil.

Conclusion

Reverse Dutch weave wire mesh is a remarkable material that meets unique industrial needs due to its strength, fine filtration capabilities, and versatility. Its applications span a wide array of sectors, from oil and gas to pharmaceuticals, emphasizing its importance in modern manufacturing and processing settings. By understanding the properties and benefits of this specialized wire mesh, industries can make informed decisions about utilizing it for efficient and effective operations. As technology continues to develop, the applications of reverse Dutch weave wire mesh are likely to expand even further, reinforcing its status as a crucial component in industrial processes.

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.