Understanding Square Mesh Screens Versatile Tools for Various Industries

Square mesh screens have emerged as essential tools in various industries due to their versatility, durability, and effectiveness in filtration, separation, and support functions. These screens, characterized by their equal-sized openings, can be manufactured from a wide range of materials, including stainless steel, aluminum, and synthetic fibers. Their design offers numerous benefits, making them indispensable in applications ranging from construction to food processing.

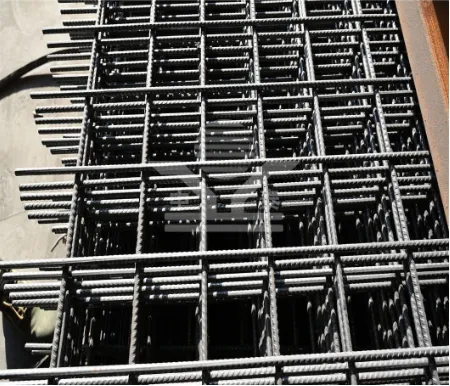

One of the most significant advantages of square mesh screens is their ability to provide consistent and uniform openings. This uniformity ensures that materials can pass through the screen at a controlled rate, making them ideal for sifting and filtration processes. In the construction industry, square mesh screens are often used in concrete reinforcement. They help maintain the structural integrity of buildings by distributing loads evenly and preventing cracks and weaknesses in concrete structures.

Moreover, square mesh screens are prevalent in the agricultural sector, where they play a crucial role in seed cleaning and soil filtration. Farmers use these screens to separate unwanted debris from seeds, ensuring that only healthy seeds are planted. Additionally, they are used for soil filtering to prevent larger particles from entering irrigation systems, thus enhancing the efficiency of water usage in agriculture.

In the food processing industry, square mesh screens are vital for ensuring product quality and safety. They are used in various applications, including sorting, washing, and drying food products. For instance, in the seafood industry, square mesh screens are employed to rinse and clean fish, removing unwanted scales and debris without damaging the delicate flesh. Similarly, they are used in the production of baked goods, where screens help sift flour and other ingredients to maintain the desired quality and texture.

square mesh screen

Another significant application of square mesh screens is in the mining and mineral processing industries. When mining for precious metals and ores, these screens are used to separate valuable materials from waste rock. Their ability to withstand harsh conditions makes them particularly suitable for this purpose. Additionally, square mesh screens can be found in the recycling industry, where they help separate different materials, facilitating the recycling process.

The versatility of square mesh screens extends to their customization. Manufacturers can create screens with specific mesh sizes and opening dimensions to suit various applications. This adaptability allows industries to optimize their processes, improving efficiency and productivity. Whether used for supporting structures, filtering liquids, or sorting materials, square mesh screens can be tailored to meet precise requirements.

In terms of maintenance, square mesh screens are relatively easy to clean and maintain. Their durable materials resist corrosion and wear, ensuring a long service life and reducing the need for frequent replacements. This longevity not only saves money for businesses but also contributes to environmental sustainability by reducing waste.

In conclusion, square mesh screens are vital tools across numerous industries, providing essential functions in filtration, separation, and support. Their uniformity, durability, and adaptability make them invaluable in construction, agriculture, food processing, mining, and recycling. As industries continue to evolve and demand higher efficiency and quality, square mesh screens will undoubtedly remain a key component in various applications, proving their importance in modern manufacturing and production processes.

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.