Understanding SS Drain Grating A Comprehensive Overview

SS drain grating, commonly referred to as stainless steel drain grating, plays a vital role in various drainage systems, be it in urban infrastructure, commercial buildings, or industrial environments. The design and functionality of these gratings are crucial for effective water management and ensuring the longevity of drainage systems.

Composition and Advantages

Stainless steel, or SS, is an alloy primarily composed of iron, carbon, and a minimum of 10.5% chromium, which contributes significantly to its corrosion resistance and strength. This makes SS drain grating an ideal choice for areas exposed to harsh weather conditions, chemicals, or heavy foot and vehicle traffic. Its durability ensures that the grating will not corrode or require frequent replacements, offering long-term cost savings.

Moreover, the aesthetic appeal of stainless steel is unmatched. With a sleek and modern finish, SS drain grating can enhance the appearance of any environment, from high-end retail spaces to bustling public areas. Its reflective surface is not just visually pleasing but also helps in maintaining cleanliness, as it highlights dirt and debris, making cleaning more efficient.

Design and Functionality

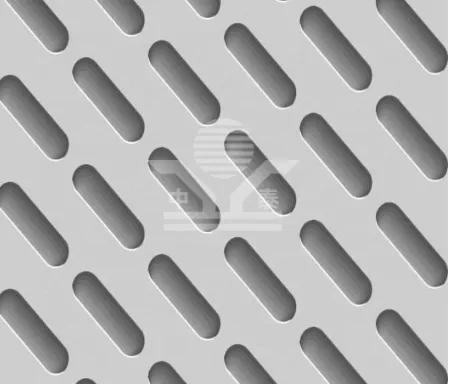

ss drain grating

SS drain gratings come in various designs, sizes, and load-bearing capacities, allowing for versatile applications. Typical designs include slotted, mesh, and perforated styles, each catering to specific drainage needs. Slotted grating, for example, is commonly used in areas requiring efficient water flow, while mesh styles might be preferred in environments where debris accumulation is a concern.

The functionality of drain gratings goes beyond mere water drainage. They also serve to prevent larger debris from entering the drainage systems, thus protecting pipes and reducing the risk of blockages. Furthermore, SS drain gratings are designed to be slip-resistant, enhancing safety in areas prone to water accumulation.

Installation and Maintenance

Installing SS drain grating is straightforward but requires precise measurements to ensure a snug fit over drainage channels. Proper installation is essential to prevent misalignment that could lead to water pooling or system failures. Maintenance involves regular cleaning to remove debris and occasional inspections to check for signs of wear or damage.

Conclusion

In summary, SS drain grating is an essential component of drainage systems across various sectors. Its combination of durability, aesthetic appeal, and functionality makes it an excellent choice for effective water management. By understanding the benefits and proper maintenance of stainless steel drain gratings, users can ensure that their drainage systems remain efficient and visually appealing for years to come. Whether for commercial, industrial, or residential use, investing in high-quality SS drain grating is a decision that pays off in both performance and longevity.

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.