Understanding Steel Grating Cost per Square Foot

Steel grating is a critical component in various industrial applications, ranging from flooring solutions to architectural designs. Known for its durability, strength, and low maintenance needs, steel grating offers a versatile and cost-effective solution for many various projects. One key aspect to consider when planning a project that involves steel grating is the cost per square foot, which can significantly influence budgeting and overall project feasibility.

Factors Influencing Steel Grating Costs

1. Material Type The type of steel used plays a significant role in determining the cost. Carbon steel is typically less expensive than stainless steel; however, the latter offers better corrosion resistance, making it more suitable for environments exposed to moisture or chemicals. Therefore, while stainless steel grating might come with a higher initial cost, its longevity may offer lower overall expenditures in the long run.

2. Grating Type There are various types of steel gratings available, including welded steel grating, pressure-locked grating, and swage-locked grating. Each type has different production processes and benefits that can affect the price. For example, welded steel grating tends to be stronger and ideal for heavy-duty applications, but it may also come with a higher price tag.

3. Dimensions and Design The dimensions of the grating panels can influence costs significantly. Custom sizes or unique designs often necessitate additional fabrication processes, which raise manufacturing costs. Standard sizes may be more economical due to mass production, making them a preferable option for large-scale projects.

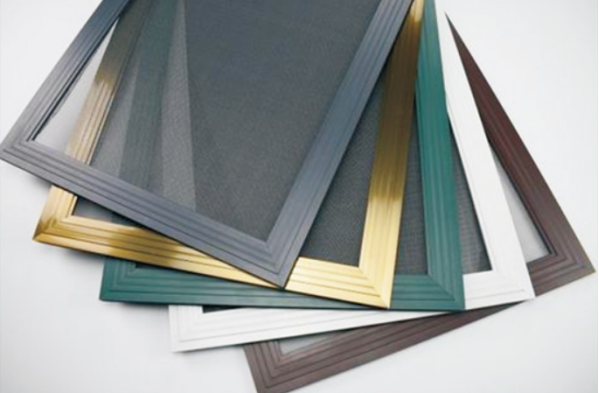

4. Surface Treatments Surface treatments like galvanization, powder coating, or painting can increase the cost of steel grating. These treatments provide additional protection against corrosion and enhance aesthetic appeal, which can be crucial for architectural applications. Ultimately, the choice of surface treatment should reflect the project’s environmental conditions and design requirements.

steel grating cost per square foot

5. Quantity and Supply Chain The quantity of steel grating required for a project also impacts the cost per square foot. Bulk purchases typically lead to discounts, lowering the overall material cost. Furthermore, supply chain factors like shipping and handling can also add to the total expenditure, especially for large or remote projects.

6. Labor Costs Although this technically falls outside the material cost per square foot, it's essential to consider the labor costs associated with installation. The complexity of the installation can vary based on the design and site conditions, so it's wise to factor in these potential costs at the planning stage.

Average Cost Estimates

On average, the cost of steel grating can range from $3 to $12 per square foot, depending on the factors mentioned above. For example, simple, untreated carbon steel grating may start at the lower end of this spectrum, while custom-sized, stainless steel grating with advanced surface treatments may approach the higher end. It is advisable to consult suppliers or manufacturers to obtain specific quotes and to assess how costs can vary based on current market conditions.

Conclusion

The cost of steel grating per square foot is influenced by multiple factors, including material type, design, and quantity. When planning a project, it’s vital to consider not only the initial material costs but also the long-term implications of different grating options. While it may be tempting to opt for the cheapest solution available, it’s important to balance upfront expenses with durability, maintenance, and performance to ensure a successful project. Understanding these dynamics can lead to informed decisions that ultimately enhance the efficiency and effectiveness of any construction or industrial application involving steel grating.

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.