Understanding Steel Grating Mesh A Versatile Solution for Industrial Needs

Steel grating mesh, a vital component in various industrial and commercial applications, is prized for its durability, strength, and versatility. Made from high-quality steel, this type of mesh is engineered to withstand heavy loads, resist corrosion, and provide a safe walking surface in environments where safety is a primary concern.

What is Steel Grating Mesh?

Steel grating mesh consists of a grid-like structure of flat bars or plates that are welded together to form a strong, open framework. The design typically features a series of parallel bars with their edges aligned vertically, which are spaced apart to create openings. These spaces allow for drainage and the passage of light and air while maintaining structural integrity. The mesh can be manufactured from various types of steel, including carbon steel and stainless steel, depending on the specific application and environmental conditions.

Types of Steel Grating Mesh

There are several types of steel grating mesh, including

1. Bar Grating This is the most common type, characterized by its flat bars. It can be manufactured in different styles such as welded, pressure-locked, or swage-locked, each offering different load-bearing capabilities and weight capacities.

2. Serrated Grating This type features serrated edges on the bearing bars, providing enhanced slip resistance. It is often used in environments where liquids may create a slippery surface, such as walkways or platforms.

3. Architectural Grating Used for aesthetic purposes as well as functionality, architectural grating combines durability with design and can be seen in commercial and public buildings.

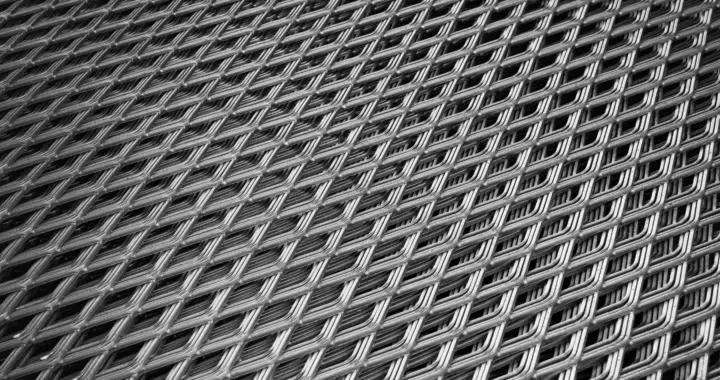

4. Expanded Metal Grating Made from a single sheet of metal that is cut and stretched to create a mesh pattern, this type of grating is lightweight and provides good ventilation and visibility.

Applications of Steel Grating Mesh

Steel grating mesh is utilized in various sectors, including

- Construction Used for flooring, stair treads, and platforms, it provides stable and strong surfaces for personnel and equipment.

steel grating mesh

- Industrial Factories and warehouses use steel grating for walkways, machine platforms, and safety barriers due to its ability to withstand heavy loads.

- Transportation This mesh is found in bridges, airports, and railway platforms for flooring and safety applications

.- Wastewater Treatment Steel grating is used in walkways and access platforms, facilitating safe and efficient maintenance.

Advantages of Using Steel Grating Mesh

The benefits of steel grating mesh are numerous, making it a popular choice across industries

- Durability Steel grating can endure harsh conditions, making it suitable for both indoor and outdoor applications.

- Safety Its open design minimizes the risk of slips and falls, especially when combined with serrated edges for added grip.

- Low Maintenance Unlike other materials, steel grating requires minimal upkeep, saving time and costs over its lifespan.

- Customizable Steel grating is available in various sizes, spacing, and finishes, allowing for customization to meet specific needs.

- Sustainability Many steel grating products are recyclable, contributing to environmentally friendly construction practices.

Conclusion

Steel grating mesh is an indispensable resource in various industries, offering a combination of strength, safety, and adaptability. As businesses continue to seek innovative solutions that enhance operational efficiency while ensuring safety, the demand for steel grating mesh is expected to grow. Understanding its features, applications, and benefits can help industries make informed decisions when selecting materials for their projects. Whether for construction, industrial applications, or architectural designs, steel grating mesh remains a top choice for professionals seeking reliability and efficiency.

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.