Understanding Swaged Grating An Innovative Approach to Metal Fabrication

In the domain of metal fabrication, innovation plays a crucial role in driving efficiency and enhancing the quality of products. One such innovation that has garnered attention in recent years is the process of swaging, particularly in applications involving gratings. Swaged grating represents a modern approach to creating high-performance metal frameworks that serve various industrial purposes. This article explores the concept of swaged grating, its benefits, applications, and the underlying technology that makes it a preferred choice in many sectors.

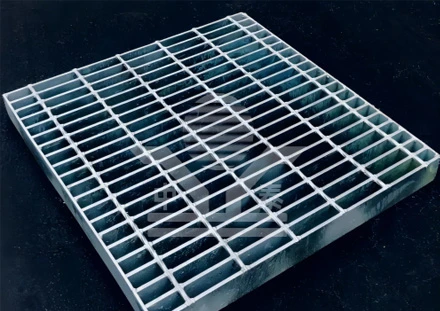

What is Swaged Grating?

Swaged grating is a method used to fabricate metal grids or gratings through a process known as swaging. This technique involves deforming metal, which allows for the creation of intricate designs and stronger profiles without the need for additional materials. In essence, swaging compresses the metal to create a tighter and more unified structure, enhancing its strength while minimizing weight. This makes swaged gratings an ideal choice in industries where strength-to-weight ratios are critical.

Benefits of Swaged Grating

1. Strength and Durability One of the most significant advantages of swaged grating is its remarkable strength. The swaging process aligns the metal's grain structure, resulting in increased tensile strength. This durability makes it suitable for high-load applications, such as walkways, platforms, and heavy machinery supports.

2. Customizability Swaged gratings can be tailored to meet specific requirements in terms of size, shape, and load-bearing capacity. This flexibility allows engineers and designers to create solutions that are perfectly suited to the needs of a particular project.

3. Reduced Weight While providing a strong structure, swaged gratings are often lighter than traditional alternatives. This reduction in weight can lead to lower transport and installation costs, as well as energy savings in applications where weight is a critical factor.

4. Corrosion Resistance Many swaged gratings are treated or coated to resist corrosion and environmental wear, which extends their lifespan, especially in outdoor or harsh industrial environments. This durability translates to lower maintenance costs over time.

5. Enhanced Aesthetics With the ability to create intricate patterns and designs, swaged grating can also serve an aesthetic purpose. It can be used as an architectural feature in public spaces, offering both functionality and visual appeal.

swaged grating

Applications of Swaged Grating

The versatility of swaged grating allows it to be utilized in various applications across multiple industries

- Construction and Architecture In buildings and public structures, swaged gratings are used in walkways, staircases, and safety barriers, providing both safety and visual interest.

- Industrial Sectors In manufacturing and processing facilities, swaged grating serves as flooring for platforms and walkways where heavy equipment is operated, ensuring safe passage and stability.

- Transportation The transportation sector employs swaged gratings in train stations and airports where strong, lightweight materials are essential for safety and design.

- Utilities In water treatment and other utility applications, swaged gratings can be used for grates and covers that need to withstand heavy loads while maintaining consistent water flow.

The Technology Behind Swaging

The swaging process employs the use of specialized machinery that can handle multiple materials, including steel, aluminum, and other alloys. The equipment typically utilizes a series of dies to create the desired shape through repeated compressive forces. Advances in computer-aided design (CAD) and manufacturing technology have allowed for more precise control of the swaging process, resulting in high-quality end products that meet rigorous industry standards.

In conclusion, swaged grating represents a remarkable advancement in metal fabrication technology. Its combination of strength, lightweight properties, and aesthetic appeal makes it a versatile choice for numerous applications. As industries continue to seek innovative solutions to meet the demands of modern engineering, swaged grating is poised to play a vital role in the future of construction, manufacturing, and beyond. By understanding its benefits and applications, businesses can make informed choices that enhance their operational efficiency and meet their design goals.

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.