Exploring Swaged Grating A Versatile Solution in Modern Engineering

Swaged grating, a term that may not be familiar to everyone, plays a crucial role in various engineering applications, particularly in the fields of construction and manufacturing. This innovative method combines the principles of metal forming and structural design, resulting in a product that is both functional and efficient. With its unique characteristics and wide range of applications, swaged grating has garnered attention as a preferred choice for many industries.

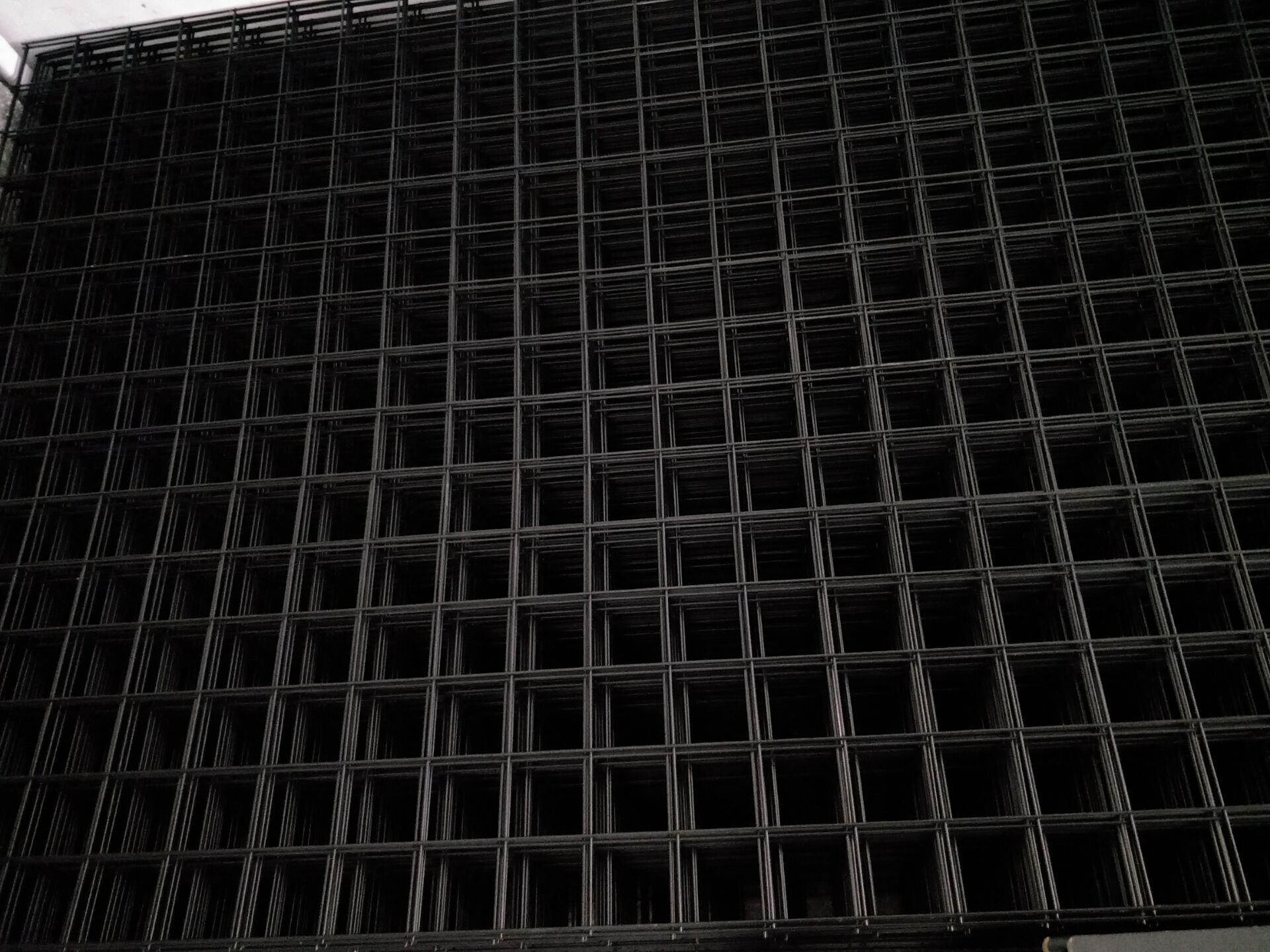

At its core, swaged grating involves the process of swaging, which is a form of metalworking that deforms a material to create desired shapes and features. In the context of grating, swaging is utilized to create a series of parallel bars or slats that are woven together, forming a strong and lightweight framework. This process not only enhances the mechanical properties of the grating but also reduces material waste—a significant advantage in today's eco-conscious manufacturing landscape.

One of the key benefits of swaged grating is its high strength-to-weight ratio. By optimizing the distribution of material, engineers can create grating that supports substantial loads while remaining lightweight. This makes swaged grating an ideal choice for applications in walkways, platforms, and staircases, where both strength and safety are paramount. In industrial settings, swaged grating can be used for flooring, allowing for safe passage over hazardous areas while facilitating drainage and airflow.

swaged grating

Additionally, swaged grating offers remarkable versatility in terms of design. The swaging process allows for various configurations, including different bar sizes, shapes, and spacing. This adaptability enables designers to tailor grating products to specific requirements, whether for aesthetic considerations in architectural projects or functional needs in industrial environments. Moreover, the ability to customize grating ensures that it can fit seamlessly into various structures, enhancing both the appearance and functionality of spaces.

Another significant advantage of swaged grating is its durability. The swaging process inherently strengthens the material, making it resistant to bending, warping, and cracking over time. This durability is particularly beneficial in outdoor applications where exposure to the elements may otherwise compromise the integrity of standard grating materials. Furthermore, many swaged gratings can be treated with coatings or finishes that enhance their resistance to corrosion, ensuring longevity even in harsh environments.

Cost-effectiveness is also a vital consideration for many businesses when selecting materials. Swaged grating can be produced efficiently, often resulting in lower manufacturing costs compared to traditional grating options. Its lightweight nature can reduce shipping costs and ease installation, allowing companies to maximize their resources effectively. In a world where budget constraints are common, swaged grating presents a viable solution that doesn't compromise on quality or performance.

In conclusion, swaged grating represents a remarkable synergy of engineering principles and practical application. Its strength, versatility, durability, and cost-effectiveness make it an invaluable resource across multiple industries. As the demand for innovative construction solutions continues to grow, swaged grating is poised to play an even more significant role in the future of design and architecture. Whether for industrial use or modern architectural projects, the benefits of swaged grating will undoubtedly make it a strong contender in the materials market. As we look towards a future focused on efficiency and sustainability, swaged grating stands out as a testament to the ingenuity of modern engineering practices.

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.