Understanding Swaged Grating An Essential Component in Modern Design and Engineering

Swaged grating is becoming an increasingly crucial component in various industries, particularly in construction, manufacturing, and engineering. This unique type of grating offers a multitude of advantages, making it an essential choice for architects and engineers who seek to enhance both functionality and aesthetics in their projects.

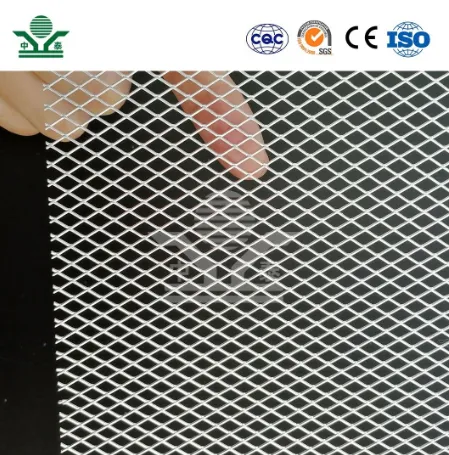

To understand swaged grating, it’s vital to grasp its definition. Swaged grating refers to a type of metal grating that is created by the swaging process—a metalworking technique that involves deforming a metal to produce a desired shape without removing any material. This process enhances the structural integrity of the grating, making it stronger and more durable than traditional grating options. Swaged grating typically consists of longitudinal bars and crossbars that form a grid-like structure, providing strength while allowing for an open space that can be used for drainage or ventilation.

One of the most significant advantages of swaged grating is its resistance to various environmental factors. In industrial settings, where exposure to harsh chemicals and heavy loads is common, the durability of swaged grating proves invaluable. The swaging process enhances the bonding between the bars, minimizing the risk of delamination or breakage under stress. As a result, swaged grating is an ideal solution for applications requiring heavy load-bearing capabilities, such as in manufacturing plants, warehouses, and even airports.

Another major benefit of swaged grating is its versatility. It can be constructed from a variety of materials, including steel, aluminum, and fiberglass. The choice of material allows for customization based on the specific needs of a project. For instance, fiberglass swaged grating is particularly beneficial in corrosive environments, such as wastewater treatment facilities, chemical processing plants, or marine applications, where metal would succumb to rust or degradation over time. Conversely, steel swaged grating provides excellent strength and is often used in industrial settings where heavy machinery operates.

swaged grating

Swaged grating is also designed to be slip-resistant, an essential feature that promotes workplace safety

. The arrangement of the bars, combined with surface treatments such as serration, ensures that individuals walking on it maintain a firm footing—even in adverse conditions. This slip resistance makes swaged grating an optimal choice for various applications, including walkways, platforms, and stair treads, thereby minimizing the risk of accidents in settings with significant foot traffic.From an aesthetic perspective, swaged grating provides a sleek and modern look that can enhance the overall design of a building or facility. Its clean lines and open structure allow for light and air to pass through, creating a more welcoming environment. Furthermore, the range of materials available allows architects to choose a finish that aligns with their design vision, from industrial-style galvanized steel to the more refined aesthetics of powder-coated aluminum.

Installation of swaged grating is another area where it excels. Assembling swaged grating systems typically requires less time and labor compared to traditional grating. The pre-fabricated nature of the product allows for straightforward installation, reducing downtime in construction or renovation projects. Innovations in design also mean that swaged grating can be pre-cut and shaped to fit any specified size or layout, leading to cost efficiency and minimal waste.

Finally, swaged grating is not only functional but also plays a role in sustainability initiatives. Many manufacturers are now focused on producing swaged grating from recycled materials, and its longevity reduces the frequency of replacements, saving resources over time. Additionally, the open structure aids in drainage and air circulation, contributing to more effective environmental management in various applications.

In conclusion, swaged grating represents a fusion of strength, versatility, safety, and aesthetic appeal. Its benefits make it a preferred choice for modern construction and engineering projects. As industries continue to prioritize efficiency, durability, and sustainability, the demand for innovative solutions like swaged grating is likely to grow. Whether in industrial applications or architectural designs, swaged grating is set to remain a pivotal element in the development of robust, safe, and visually appealing infrastructures.

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.