1 月 . 09, 2025 10:52

Back to list

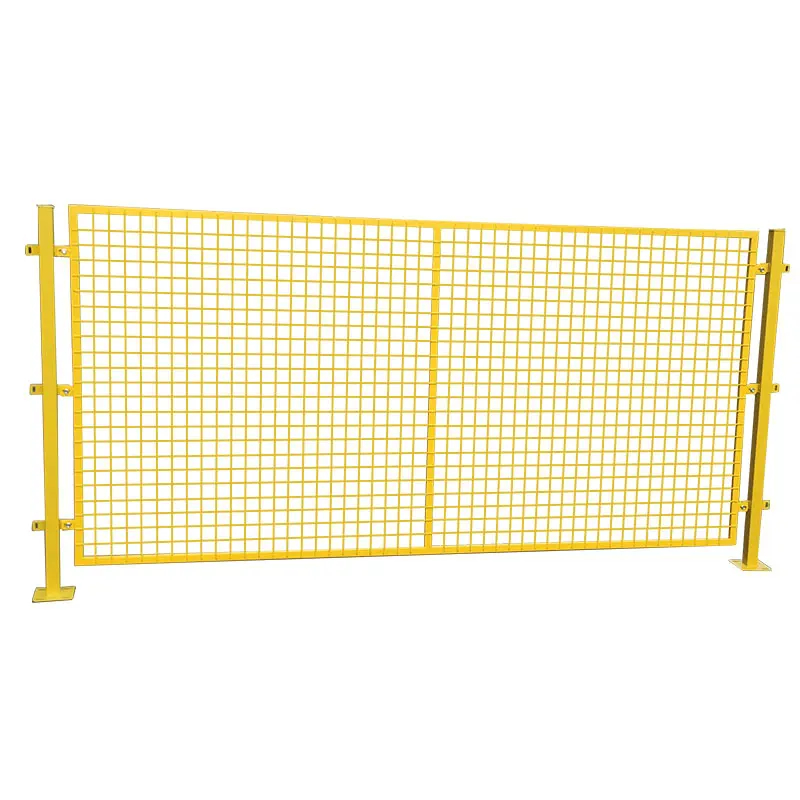

types of expanded metal mesh

Expanded metal mesh, a versatile material recognized for its strength and utility, is available in various types designed to meet specific needs across different industries. As a product deeply rooted in modern architecture, industrial applications, and even interior design, understanding the diverse types of expanded metal mesh can facilitate informed decisions for projects requiring aesthetic appeal, security, and functionality.

Flattened expanded metal mesh undergoes an additional cold-rolling process after expansion, which smoothens the surface and elongates the formations. This type of mesh features a more leveled appearance, enhancing its suitability for applications where a smoother surface is desired, such as shelving, ramps, and platforms. The smooth finish not only improves the visual appeal but also reduces the risk of snagging, making it safer for pedestrian traffic. Heavy-duty expanded metal mesh is engineered for the toughest environments, providing unparalleled strength and resilience. This type is often employed in military applications, heavy machinery, and high-security fencing. Its ability to withstand harsh environmental conditions and significant physical stress makes it indispensable for projects demanding robust security solutions. For those in industries such as automotive, aerospace, or any field requiring precision-engineered solutions, precision expanded metal mesh offers the perfect blend of strength and accuracy. Manufactured using cutting-edge technology, this mesh type is engineered for applications where precise dimensional tolerances are critical. Its reliable performance enhances the overall efficiency and safety of complex systems. Each type of expanded metal mesh presents unique advantages tailored to specific applications, underscoring the importance of selecting the right mesh for the intended use. Whether for industrial use, architectural flair, or high-security requirements, understanding these classifications empowers professionals to make choices that optimize both functionality and aesthetics. Additionally, collaborating with a reputable supplier who can provide insights into material properties and project suitability further enhances decision-making, ensuring that the chosen solution aligns perfectly with project objectives.

Flattened expanded metal mesh undergoes an additional cold-rolling process after expansion, which smoothens the surface and elongates the formations. This type of mesh features a more leveled appearance, enhancing its suitability for applications where a smoother surface is desired, such as shelving, ramps, and platforms. The smooth finish not only improves the visual appeal but also reduces the risk of snagging, making it safer for pedestrian traffic. Heavy-duty expanded metal mesh is engineered for the toughest environments, providing unparalleled strength and resilience. This type is often employed in military applications, heavy machinery, and high-security fencing. Its ability to withstand harsh environmental conditions and significant physical stress makes it indispensable for projects demanding robust security solutions. For those in industries such as automotive, aerospace, or any field requiring precision-engineered solutions, precision expanded metal mesh offers the perfect blend of strength and accuracy. Manufactured using cutting-edge technology, this mesh type is engineered for applications where precise dimensional tolerances are critical. Its reliable performance enhances the overall efficiency and safety of complex systems. Each type of expanded metal mesh presents unique advantages tailored to specific applications, underscoring the importance of selecting the right mesh for the intended use. Whether for industrial use, architectural flair, or high-security requirements, understanding these classifications empowers professionals to make choices that optimize both functionality and aesthetics. Additionally, collaborating with a reputable supplier who can provide insights into material properties and project suitability further enhances decision-making, ensuring that the chosen solution aligns perfectly with project objectives.

Latest news

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP