1 月 . 09, 2025 11:51

Back to list

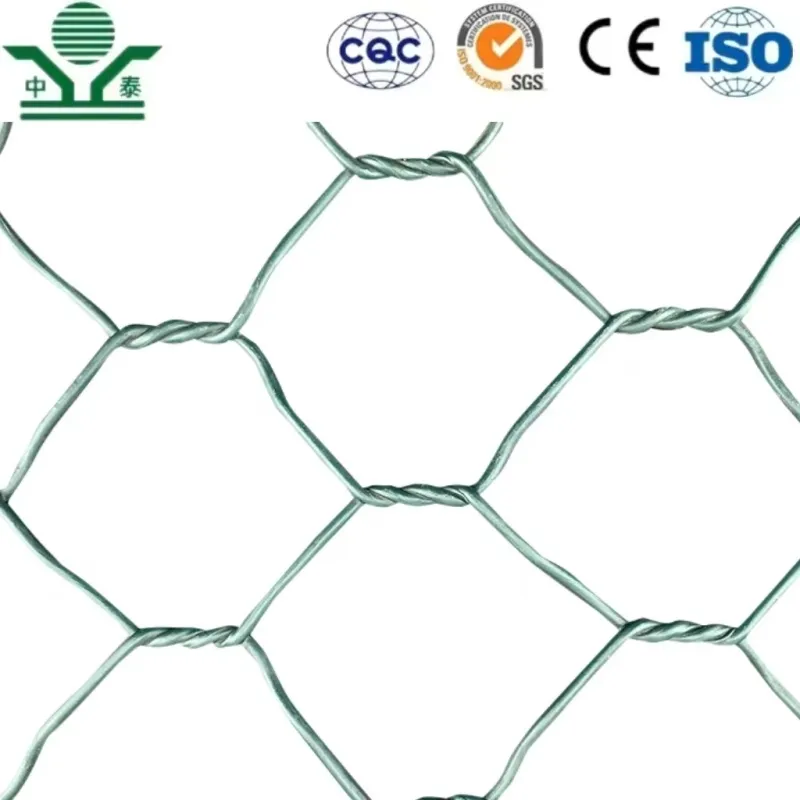

Expanded Metal Mesh for sale

Expanded metal mesh, a versatile and robust material, is increasingly finding its place across various industries due to its unique attributes. This comprehensive insight into the types of expanded metal mesh aims to enlighten stakeholders on making informed decisions based on practical experience, expert recommendations, and authoritative insights.

For modern design enthusiasts, architectural expanded metal mesh brings both art and utility. Embraced by architects and designers, this type enhances the aesthetic value of structures while providing functional benefits like shading and ventilation. Its adaptability in terms of material, pattern, and finish makes it a sought-after component in facades, ceilings, and interior partitions. Beyond the types themselves, selecting the appropriate expanded metal mesh involves understanding material properties—aluminum for lightweight applications, steel for strength, stainless steel for corrosion resistance, and copper for conductivity. Each material brings unique benefits and limitations, impacting the performance and longevity of the final product. Expertise in expanded metal mesh selection also considers environmental factors and specific use-case scenarios. For instance, in environments exposed to harsh weather conditions, choosing the right coating could extend the lifespan and appearance of the mesh. Galvanized coatings, powder coating, or anodizing offer varying levels of protective barriers, making it crucial for the selection process to assess environmental exposure and maintenance capacities. Authoritative insights suggest that while expanded metal mesh is a mature technology, advancements continue to emerge. Innovations in manufacturing processes, such as laser cutting and digital modeling, enhance precision and customization capabilities. These technological enhancements allow for unprecedented levels of creativity and efficiency, expanding the scope of applications. Trustworthiness in product selection leans heavily on the reputation and certification of manufacturers. Industry standards, such as ISO certifications, provide a layer of assurance regarding the quality and consistency of expanded metal mesh. Engaging with reputable suppliers ensures access to materials that meet international standards and deliver performance as promised. In conclusion, understanding the various types of expanded metal mesh and the nuanced factors influencing their application empowers stakeholders to make informed decisions. The continuous evolution of this material, driven by market demands and technological advancements, promises to keep expanded metal mesh at the forefront of innovation in design, security, and industrial applications. Whether for its strength, aesthetics, or versatility, expanded metal mesh remains a cornerstone material with unrivaled potential.

For modern design enthusiasts, architectural expanded metal mesh brings both art and utility. Embraced by architects and designers, this type enhances the aesthetic value of structures while providing functional benefits like shading and ventilation. Its adaptability in terms of material, pattern, and finish makes it a sought-after component in facades, ceilings, and interior partitions. Beyond the types themselves, selecting the appropriate expanded metal mesh involves understanding material properties—aluminum for lightweight applications, steel for strength, stainless steel for corrosion resistance, and copper for conductivity. Each material brings unique benefits and limitations, impacting the performance and longevity of the final product. Expertise in expanded metal mesh selection also considers environmental factors and specific use-case scenarios. For instance, in environments exposed to harsh weather conditions, choosing the right coating could extend the lifespan and appearance of the mesh. Galvanized coatings, powder coating, or anodizing offer varying levels of protective barriers, making it crucial for the selection process to assess environmental exposure and maintenance capacities. Authoritative insights suggest that while expanded metal mesh is a mature technology, advancements continue to emerge. Innovations in manufacturing processes, such as laser cutting and digital modeling, enhance precision and customization capabilities. These technological enhancements allow for unprecedented levels of creativity and efficiency, expanding the scope of applications. Trustworthiness in product selection leans heavily on the reputation and certification of manufacturers. Industry standards, such as ISO certifications, provide a layer of assurance regarding the quality and consistency of expanded metal mesh. Engaging with reputable suppliers ensures access to materials that meet international standards and deliver performance as promised. In conclusion, understanding the various types of expanded metal mesh and the nuanced factors influencing their application empowers stakeholders to make informed decisions. The continuous evolution of this material, driven by market demands and technological advancements, promises to keep expanded metal mesh at the forefront of innovation in design, security, and industrial applications. Whether for its strength, aesthetics, or versatility, expanded metal mesh remains a cornerstone material with unrivaled potential.

Latest news

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP