1 月 . 16, 2025 05:19

Back to list

Traffic Trench Drain Grate China Manufacturing Metal Security Window Grates

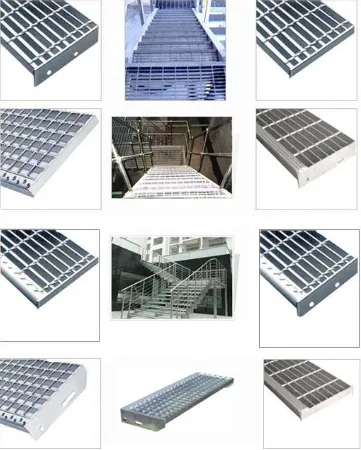

Custom bar grating stands as a pivotal component in numerous industrial and commercial applications, offering a robust blend of strength, versatility, and durability. These gratings, crafted from a series of bearing bars and cross rods, provide enhanced support and safety, becoming essential in structures that demand high performance under heavy loads.

For designers and business owners, understanding the installation and maintenance of custom bar grating is crucial. Installation is straightforward but must be conducted by trained professionals to ensure secure fastening and alignment. Regular inspections and maintenance, such as cleaning to prevent the buildup of debris and checking for signs of wear, are vital in prolonging the life of the grating. In terms of authority and trustworthiness, manufacturers of custom bar grating often adhere to stringent industry standards, offering products certified by organizations like the American National Standards Institute (ANSI) or the Occupational Safety and Health Administration (OSHA). This compliance not only attests to the quality of the grating but also assures clients of their safety and reliability. Customers can further rely on a manufacturer’s expertise, backed by years of experience and a proven track record in producing top-tier grating solutions. Ultimately, choosing custom bar grating is an investment in safety, durability, and efficiency. Its proven effectiveness in high-demand applications and its ability to be customized to fit unique project specifications make it a preferred choice among industry professionals. By leveraging advancements in materials and manufacturing technology, custom bar grating not only meets but also anticipates the dynamic needs of contemporary infrastructure development.

For designers and business owners, understanding the installation and maintenance of custom bar grating is crucial. Installation is straightforward but must be conducted by trained professionals to ensure secure fastening and alignment. Regular inspections and maintenance, such as cleaning to prevent the buildup of debris and checking for signs of wear, are vital in prolonging the life of the grating. In terms of authority and trustworthiness, manufacturers of custom bar grating often adhere to stringent industry standards, offering products certified by organizations like the American National Standards Institute (ANSI) or the Occupational Safety and Health Administration (OSHA). This compliance not only attests to the quality of the grating but also assures clients of their safety and reliability. Customers can further rely on a manufacturer’s expertise, backed by years of experience and a proven track record in producing top-tier grating solutions. Ultimately, choosing custom bar grating is an investment in safety, durability, and efficiency. Its proven effectiveness in high-demand applications and its ability to be customized to fit unique project specifications make it a preferred choice among industry professionals. By leveraging advancements in materials and manufacturing technology, custom bar grating not only meets but also anticipates the dynamic needs of contemporary infrastructure development.

Latest news

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP