1 月 . 16, 2025 05:40

Back to list

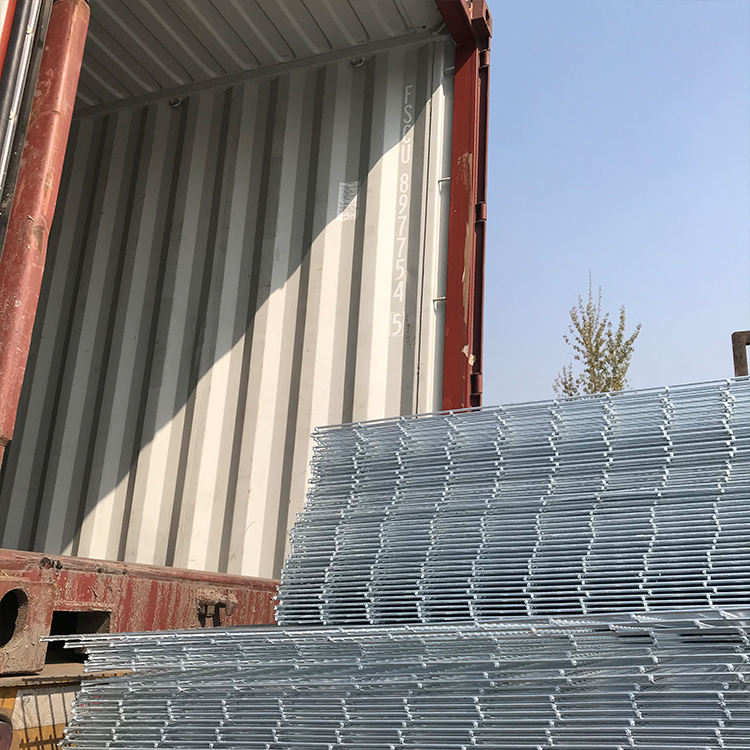

Metal Tree Grate China Factory Bunny Litter Box Grate

Welded bar grating, an essential component in the industrial flooring industry, serves a multitude of applications ranging from stair treads and catwalks to decking and drainage covers. Its robustness and durability make it a prime choice for environments demanding uncompromising strength and reliability. However, what often gets overlooked is the expertise and precision that goes into crafting these versatile products.

Various types of welded bar grating cater to distinct professional requirements. Standard options include light-duty and heavy-duty gratings, each engineered for specific load capacities and applications. Furthermore, customization is key in meeting project specifications, whether it’s for grates in chemical plants, grids in parking garages, or secured platforms in airports. Moreover, an authoritative approach to quality assurance ensures that these products meet stringent safety standards. In particular, manufacturers often adhere to specifications set by authorities such as the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA) to guarantee structural integrity and user safety. One notable aspect, attesting to the product's trustworthiness, is the attention given to quality control during the production phase. This includes rigorous testing for load resistance and environmental impact, ensuring that the grating remains durable and efficient over time. Trustworthiness is further reinforced by industry certifications and client testimonials, solidifying claims of reliability and performance. In summation, welded bar grating not only embodies epitomes of industrial design and craftsmanship but also serves as a critical asset in enhancing workplace safety and functionality. By choosing superior quality welded bar grating, industries gain more than just a product; they receive assured expertise and trustworthiness, embedded within each welded joint and grid pattern. Whether your focus is on upgrading an existing infrastructure or constructing a new facility, the proven efficacy and dependability of welded bar grating make it an unmatched choice.

Various types of welded bar grating cater to distinct professional requirements. Standard options include light-duty and heavy-duty gratings, each engineered for specific load capacities and applications. Furthermore, customization is key in meeting project specifications, whether it’s for grates in chemical plants, grids in parking garages, or secured platforms in airports. Moreover, an authoritative approach to quality assurance ensures that these products meet stringent safety standards. In particular, manufacturers often adhere to specifications set by authorities such as the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA) to guarantee structural integrity and user safety. One notable aspect, attesting to the product's trustworthiness, is the attention given to quality control during the production phase. This includes rigorous testing for load resistance and environmental impact, ensuring that the grating remains durable and efficient over time. Trustworthiness is further reinforced by industry certifications and client testimonials, solidifying claims of reliability and performance. In summation, welded bar grating not only embodies epitomes of industrial design and craftsmanship but also serves as a critical asset in enhancing workplace safety and functionality. By choosing superior quality welded bar grating, industries gain more than just a product; they receive assured expertise and trustworthiness, embedded within each welded joint and grid pattern. Whether your focus is on upgrading an existing infrastructure or constructing a new facility, the proven efficacy and dependability of welded bar grating make it an unmatched choice.

Latest news

-

Turn Down the Noise: The Future of Highway Sound Barriers

NewsApr.09,2025

-

Silence the Sound: The Power of Highway Noise Barriers

NewsApr.09,2025

-

Reduce Road Noise Effectively with Highway Noise Barriers

NewsApr.09,2025

-

Noise-Free Living: How Highway Barriers Make a Difference

NewsApr.09,2025

-

Engineered for Silence: Highway Noise Barriers for Every Road

NewsApr.09,2025

-

Effective Noise Control: Highway Barriers for a Quieter Tomorrow

NewsApr.09,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP